We’re excited about this next generation of students finishing their studies with demonstrated practical abilities to use 3D printing technology, and a thirst to change the way we design and build. From the BigRep Innovation Award, which recognizes 3D design talent, to working with universities and students on realizing their complex prototyping projects, BigRep is committed to supporting education about FFF and additive manufacturing.

A new video by BigRep zooms in on three innovative projects that are underway at universities in Denmark, Germany and Britain, all of which exemplify the potential of 3D printing and how it can enhance tertiary or vocational education.

One engineering student at Kingston University in London has been designing a 3D-printed injector for a rocket engine and spoke about how the 3D printer has transformed the way designs are developed in real life for testing. Creating a design, producing it, machining it to make changes – this process can be difficult and time-consuming, but the 3D printer makes it easy to develop multiple versions for testing at the same time for a faster turnaround.

One student project has involved using Kingston University’s BigRep ONE to print molds for Caterham racing car parts, such as a carbon fiber door for the driver. As engineering lecturer Dave Haskell says, they print the pieces, which can then go straight into the wind machine for testing.

As Haskell puts it, a main benefit of large-scale 3D printers is that they do not limit your imagination. Practically, you can print big. He says that if there’s any easier way to do it, an engineer will find it. For example, 3D printing is so much easier than trying to make something out of foam. We would also argue, that if there’s a more innovative way of doing something, clued-in students are likely to find it.

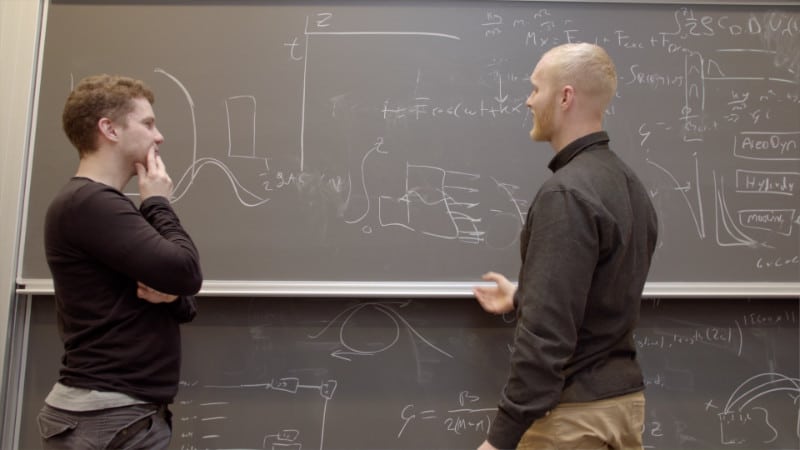

At Aalborg University, a pair of students doing their Masters in Offshore Energy Systems are working on a project to create a floating turbine. The blackboard where the pair have sketched out their calculations looks like a jumble of numbers to the average untrained eye, but it represents the working out on a complex design for the 3D printer. They have scaled the design and printed it large scale to test.

For more information and video content on the exciting 3D-printed bicycle project at Aalborg University, which was covered on Plastics Today and All3DP, then click here to watch the bike in action. Just quietly, we’re curious to see whether their frame would work with our world-first, 3D-printed bike tires, printed using our TPU-based Pro FLEX.

The Technical University (TU) Wildau in Brandenburg, Germany, has a BigRep 3D printer that their engineering students use to develop prototypes with different functionalities. In the video, TU Wildau’s FabLab Manager and Ph.D. candidate Markus Lahr, shows a 3D-printed casing for a gear.

He speaks of the great opportunity that large-scale 3D printing technology brings to students to bring their ideas to life in such a formative time in their professional lives and education. An extended video by BigRep offers insight on another student project at TU Wildau, involving printing a bicycle with the BigRep ONE.

Though it is not only university-age students that should be learning about FFF! Guillaume Kouyoumdjian, BigRep’s Head of Online Services, recently gave a presentation on 3D printing to his daughter’s 5th grade class at the bilingual French-German Märkische Grundschule in Berlin.

Using a small 3D printer – for space and time reasons it was not possible to use a BigRep large-scale printer! – Kouyoumdjian showed the young students how to design, slice and print a small object in 30 minutes as part of his presentation. The object was used as part of an interactive story aimed at showing the children how 3D printing could easily reproduce objects. Most of the students had never heard of 3D printing before, and one student exclaimed, "I have so many questions in my head. 45 minutes was much too short!"

Class teacher Ms Bénédicte Sigalas said, “There was a well-established link between the different subjects the children are studying and their daily lives. The presentation on the evolution of past, present and future jobs was very interesting.”

We look forward to hearing how some of these students are changing the face of additive manufacturing a decade down the track!