This summer we moved to our new premises in Berlin-Kreuzberg. At the beginning the spacey loft was empty but quickly it filled up with our fast growing team, and now it is packed with printers, because the production of our brand new model BigRep ONE.2 is in full swing. These days transport boxes are lining up in our premises in Kreuzberg, waiting to be packed with printers and then shipped to our customers all over the world. At this very moment, we are shipping printers to universities, world known software companies, mold makers, foundries, service providers, designers, artists and diverse users in the field of rapid prototyping in Europe, the USA and Asia.

On the road again … to EuroMold2014

At EuroMold2014 from 25-28 November in Frankfurt we presented our updated serial model, the BigRep ONE.2. Prototypes, models or molds as well as products for end users like designer furniture can be printed out directly due to the giant printing volume of 1,3m³. As a proof of our concept we brought a real case study for manufacturing with us to Frankfurt: BigRep ONE.2 printed full-scale molds for glass blowing in a size of 40 x 60 cm. With these molds, a glassmaking factory produced full-size glass cups.

The sale is on

What´s the use of the best 3D printer in the world, if you can´t buy it? At BigRep we have been literally overwhelmed by the huge interest in our giant printers from the beginning. Now, the first printers have been shipped, production is ramping up and we have established a worldwide resellers network which is growing every month. In September, we hosted our first BigRep global resellers meeting. Here´s the list of our partners (in alphabetical order): China, Czech Republic, France, Israel, Italy, India, Jordan, Lithuania, UK, United Arab Emirates and Russia. This only for the time being, our resellers is growing by every month. So, if you are interested in buying one of our printers (sure you are!), you should have a look here from time to time. You´ll find all the updated contact details by contacting us here. Or send us an e-mail and we will route you to the next BigRep dealer.

The man who prints houses visits BigRep

We at BigRep are used to think in large scales. Our printers have a printing volume of up to 1,5 cubic meters (53 cubic feet) and they are the largest serial 3D printers on the market at the moment. But this Italian Gentleman, who popped in at our booth at 3D Printshow in London today is a real giant. He was the first to build a working 3D printer for printing buildings and became world famous as “The Man Who Prints Houses’.

Dini spent a fortune on the development of his machine and the promotion of his ideas. He even ruined his privat life, but he is still going on. Two years ago, Dini developed the “Moebius House”. The house has the shape of a Moebius strip and is made up of printed elements. And Dini is even printing houses for fish! He printed an artificial coral reef, which is being tested in Bahrain. The elements serve as breakwaters, but their complex organic shapes also offers protection to fish and other sea creatures.

Dini´s visit was a great inspiration for us. We can learn a whole lot from this brilliant visionary. And on thing is for sure: Think big and never give up!

Resellers from all over the world at BigRep HQ

The pace is high at BigRep. We barely had unpacked our stuff from moving into our new, 1000 square meters loft in Berlin-Kreuzberg, when last week our Resellers from all over the world flew in for the first BigRep global resellers meeting. Our partners come from UK, France, Israel, Russia, Lithuania, China and India. During two Days we discussed technical features, customer´s support, trade shows and pricing. And had fun eating giant Wiener Schnitzels at “Austria”, a famous Austrian Restaurant two blocks from our premises. We are looking forward to working with you guys and building a strong network for seamless customer support.

Now we pack again and head for 3D Printshow in London from September 4th to 6th. We are nominated there as “Business Newcomer of the Year”. You can vote for us here: http://3dprintshow.com/global-awards/best-business-newcomer/

BigRep on Tech Open Air

Meet us and BigRep ONE at TOA Berlin.

Tech Open Air Berlin is Europe’s leading interdisciplinary technology festival: this year we expect 2,500+ visitors, 100+ international speakers (including Indiegogo’s Danae Ringelmann, SXSW’s James Minor, SKULLY's Marcus Weller, AKQA’s James Hilton and many others) from 30+ countries as well as 75+ satellite events (incl. Twitter, Spotify, Apple, Ableton, Soundcloud, Indiegogo, TechCrunch) and 100+ international media outlets including CNN, BBC, WSJ, ARD, ZDF, RTL, TechCrunch, TNW, Bild, Vice and Welt.

TOA14 will be presented in cooperation with MINI (BMW) and will take place from July 16-17 at Alte Teppichfabrik, a formerly abandoned factory in Berlin’s city centre. On the first day will curate an "unconference” which also features live music and art installations, while on the second day the community takes over with satellite events all over town.

Designing with Nature – The Architecture Foundation presents first-ever solo show of Exploration Architecture

NOW OPEN – Designing with Nature: The Architecture Foundation presents the first-ever solo show of Exploration Architecture

[…]

Showcasing Exploration’s working philosophy and embracing 3D printing’s capacity for radically increased resource efficiency, the exhibition’s central installation takes the form of a long sweeping display designed to showcase innovative SKO software – a structural optimisation computer programme based on the adaptive growth patterns of trees and bones – and has been created with support from large-scale 3D printing pioneer Lukas Oehmigen of BigRep.

[…]

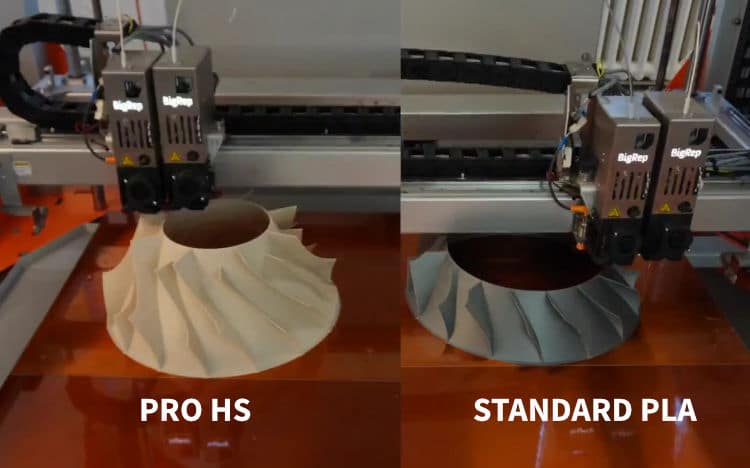

BigRep Launches High-Speed PRO HS Filament

- BigRep Pro HS Filament reduces printing time by up to 50 percent

- No machine modification necessary

- Ideal for large format objects and prototypes

Cost-efficient production is essential in times of smart production. With Pro HS, the Berlin-based technology start-up BigRep brings a unique printing filament to the market. The innovative material reduces production times in 3D printing by up to 50 percent and makes additive manufacturing more efficient and cost-effective for companies.

The BigRep Pro HS Filament is, in addition to the high-temperature-resistant filament Pro HT, the second product of the BigRep "Industrial Filament" line. The mechanical properties and also the printability of Pro HS are similar to those of PLA, but the material is somewhat more robust and has twice the flowability. The production of this non-oil-based biopolymer is also much more environmentally compatible than that of ABS plastics. The raw materials come from sustainable and renewable resources.

Pro HS can be used in various industrial areas, but is particularly suitable for printing large-format objects and prototypes. "With the BigRep Pro HS Filament we have developed a versatile material. In addition to the significantly reduced printing time, a major advantage of the product is that machines do not need to be modified for the application. It can be used on both new and older BigRep models. Especially when working with our large-format printers BigRep ONE and BigRep STUDIO, we offer our customers a flexible, complete solution for the most diverse requirements", explains René Gurka, CEO of BigRep GmbH.

BigRep Pro HS Filament is available in natural and basalt colors. Both paints are matt after extrusion and give the objects a refined look - even at large layer heights. On request, the color can be customized.

The BigRep Filament Pro HS is now available in the three coil sizes 2.5 kg, 4.5 kg and 8 kg in 2.85mm diameter in the BigRep-Onlineshop.

BigRep Pro HS Filament - Technical Data:

Material: BioPolymer

Density: 1.4 g / cm³

Diameter: 2.85 mm

Print Temperature Guideline: 170 - 210 ° C

Heating Bed: 0 - 60 ° C

Heat Distortion Temperature (ISO 75): 48 ° C

Tensile Strength (ISO 527): 43 MPa

Impact Strength (ISO 179): 59 KJ / m²

Flexural Modulus (ISO 178): 3500 MPa

About BigRep:

BigRep is a technology start-up with headquarters in Berlin and offices in New York and Singapore. One of the groundbreaking developments of the company founded in 2014 is the BigRep ONE, which is supplemented by the smaller BigRep STUDIO. Interdisciplinarity and well-founded experience in the field of additive production characterize the multi-national team of BigRep, now more than 60 employees. In addition to new products, the Berlin Kreuzberger company is now concentrating on complete solutions for industrial customers in the form of integrated additive manufacturing systems. Such as the continuous printing project with TNO, which was announced in Autumn 2016. The aim of the highly innovative engineering company is to revolutionize design, prototyping and industrial production from the ground up. Over the next five years, BigRep intends to become a leading international supplier of additive manufacturing systems.

For further information as well as picture and video material please contact:

Maik Dobberack

PR & Kommunikation

BigRep GmbH

T +49 30 208 4826-38

E [email protected]

More information:

Web www.bigrep.com

Facebook www.facebook.com/BigRep

Twitter www.twitter.com/BigRep

3D Printing The Next Five Years by René Gurka CEO and co-founder of BigRep

This is a guest post in our series looking at the future of 3D Printing. To celebrate 5 years of reporting on the 3D printing industry, we’ve invited industry leaders and 3D printing experts to give us their perspective and predictions for the next 5 years and insight into trends in additive manufacturing.

René Gurka is the CEO and co-founder of BigRep. Headquartered in Berlin-Kreuzberg, with offices in Brooklyn and Singapore, he has been actively involved in the future of additive manufacturing together with his international interdisciplinary team for the last three years.

3D Printing: The Next Five Years – Industrial 3D Manufacturing is the Ultimate Goal

If you want to look at the future of 3D printing, it is worthwhile looking back in time; additive manufacturing has been around for about 30 years. But only in the past five years has it gained this big recognition. The promise was: everyone can print objects at home with a 3D printer and become a designer. “We wanted people to 3D print anything” said 3D industry pioneer Bre Pettis in 2013. But these high expectations have not been fully realized. Except for a few talented individuals, home use of 3D printers has not hit the mainstream. The reason is simple: most of us lack the necessary design and construction understanding to be able to use the devices productively, or the skills to create the necessary digital data at home.

Traditional Production will be Disrupted

The question arises that if this vision was wrong, what is the realistic development in next five years in 3D printing? For BigRep, the answer is clear: the focus will shift from individual users to industrial production. And by this I do not mean the production of prototypes, because this is already firmly established, especially with large manufacturers. The trend is rather towards automated additive production. 3D printing will become an integral part of industrial production and the traditional production process will change disruptively. This is made possible by the close interaction between software and cloud services, materials and robotics in additive manufacturing (AM). Similar to 3D printing, these have undergone an enormous development in recent years.

Keep reading…. (on 3dprintingindustry.com)