- Körber invests in the Berlin technology start-up BigRep as part of the current B-financing round

- Körber is the perfect strategic partner for BigRep

Just only over three years after the founding, the Berlin technology start-up BigRep wins the international technology company Körber AG as a further investor in its current B-financing round. The partnership was officially announced today.

For BigRep, manufacturer of the world's largest 3-D printer and supplier of additive manufacturing systems, this is an important next step in their growth. "Through this additional investment in our company, we are able to further expand the development and solutions as well as increase our global footprint and sales," says René Gurka, CEO of BigRep. "Körber is a very experienced technology company that can support us not only financially, but also in industrial machine building. We are looking forward to working with our new colleagues. "

At Körber, too, all signs point to growth. The strategic investments of the Group are focused on future technologies and markets. "Since its founding 2014, BigRep has developed into a competitive, steadily growing company with more than 70 employees and offices in the US and Asia," said Michael Horn, member of Körber AG's Board of Management. "In addition to our existing know-how, we want to explore the possibilities of additive manufacturing even more intensively through our joint venture with the IRPD through our participation in BigRep. In addition, we will use these competencies within our business areas for further customer applications development."

In addition to kloeckner.v, the Venture Capital Subsidiary of Klöckner & Co SE, Körber AG is the second investor to participate in the current financing round.

About BigRep:

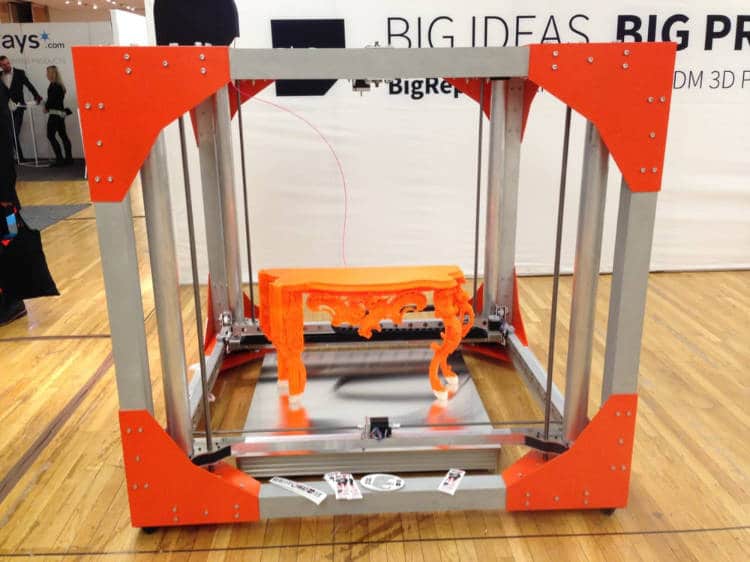

BigRep is a technology start-up based in Berlin with offices in New York and Singapore, which develops and manufactures the world's largest 3-D printer. One of the groundbreaking developments of the company founded in 2014 is the BigRep ONE, which is supplemented by the smaller BigRep STUDIO. Interdisciplinarity and well-founded experience in the field of additive manufacturing characterize the multi-national team of BigRep, now more than 70 employees. In addition to new products, the Berlin company is now concentrating on complete solutions for industrial customers in the form of integrated additive manufacturing systems. One example is the TNO project, which is scheduled to be released in Summer 2018. The goal of the highly innovative engineering company is to revolutionize design, prototyping and industrial production from the ground up. Over the next five years, BigRep intends to become a leading supplier of additive manufacturing systems.

About Körber:

Körber is an international technology group with around 11,500 employees worldwide. It brings together technologically leading companies with more than 130 production, service and sales companies. At locations around the world, Körber combines the advantages of a globally present organization with the strengths of highly specialized and flexible medium-sized companies that offer their customers solutions, products and services in the fields of automation, logistics systems, machine tools, pharmaceutical systems and tissue, Tobacco and business interests. The Körber Group generated sales of EUR 2.2 billion in the 2016 financial year.

About Klöckner & Co:

Klöckner & Co is one of the largest producer-independent distributors of steel and metal products and one of the leading steel service center companies worldwide. Based on its distribution and service network of around 170 locations in 12 countries, the Group supplies more than 130,000 customers. In addition to companies in the construction industry as well as machinery and mechanical engineering, Klöckner & Co serves customers in the automotive and chemical industry, in shipbuilding and in fields of household appliances, consumer goods and energy. Currently Klöckner & Co has around 8,700 employees. The Group had sales of around €5.7 billion in fiscal 2016.

The shares of Klöckner & Co SE are admitted to trading on the regulated market segment (Regulierter Markt) of the Frankfurt Stock Exchange (Frankfurter Wertpapierbörse) with further post-admission obligations (Prime Standard). Klöckner & Co shares are listed in the SDAX®-Index of Deutsche Börse.

ISIN: DE000KC01000; WKN: KC0100; Common Code: 025808576.

For further information as well as pictures and video material please contact:

Maik Dobberack

PR & Communication

BigRep GmbH

T +49 (0) 30 208 4826-38

E [email protected]

Contact Körber AG:

Henriette Viebig

Head of Corporate Communications

Körber AG

T +49 40 21107-422

E [email protected]

Contact Klöckner & Co SE:

Christian Pokropp

Head of Corporate Communications

Klöckner & Co SE

T + 49 (0) 203-307-2050

E [email protected]