For the first time ever a consumer water sports mobility device will be 75% additively manufactured (AM) with serial-produced, custom 3D-printed parts: The AMAZEA scooter’s body and front parts are being produced on three BigRep ONE large-format 3D printers using engineering-grade materials by BigRep, the global leader in large-scale 3D printing and additive solutions.

"AMAZEA is an industry-first breakthrough with the potential to redefine maritime vehicle technology and the consumer experience in water sports around the world,” said JAMADE Managing Partner Janko Duch, who founded the company together with Martin Oser and Detlef Klages in July 2018. “We opted for the BigRep ONE due to its cost efficiency, accuracy and quality when compared to the extremely high investment for traditional tools, particularly in the first year’s lower quantity,” the founders explained. German-based JAMADE is specialized in the development and manufacturing of e-powered water sports equipment for the end consumer market.

The large-format BigRep ONE 3D printer was key to a successful product launch, providing the high flexibility and speed AM offers, also making the development process much more time-efficient.

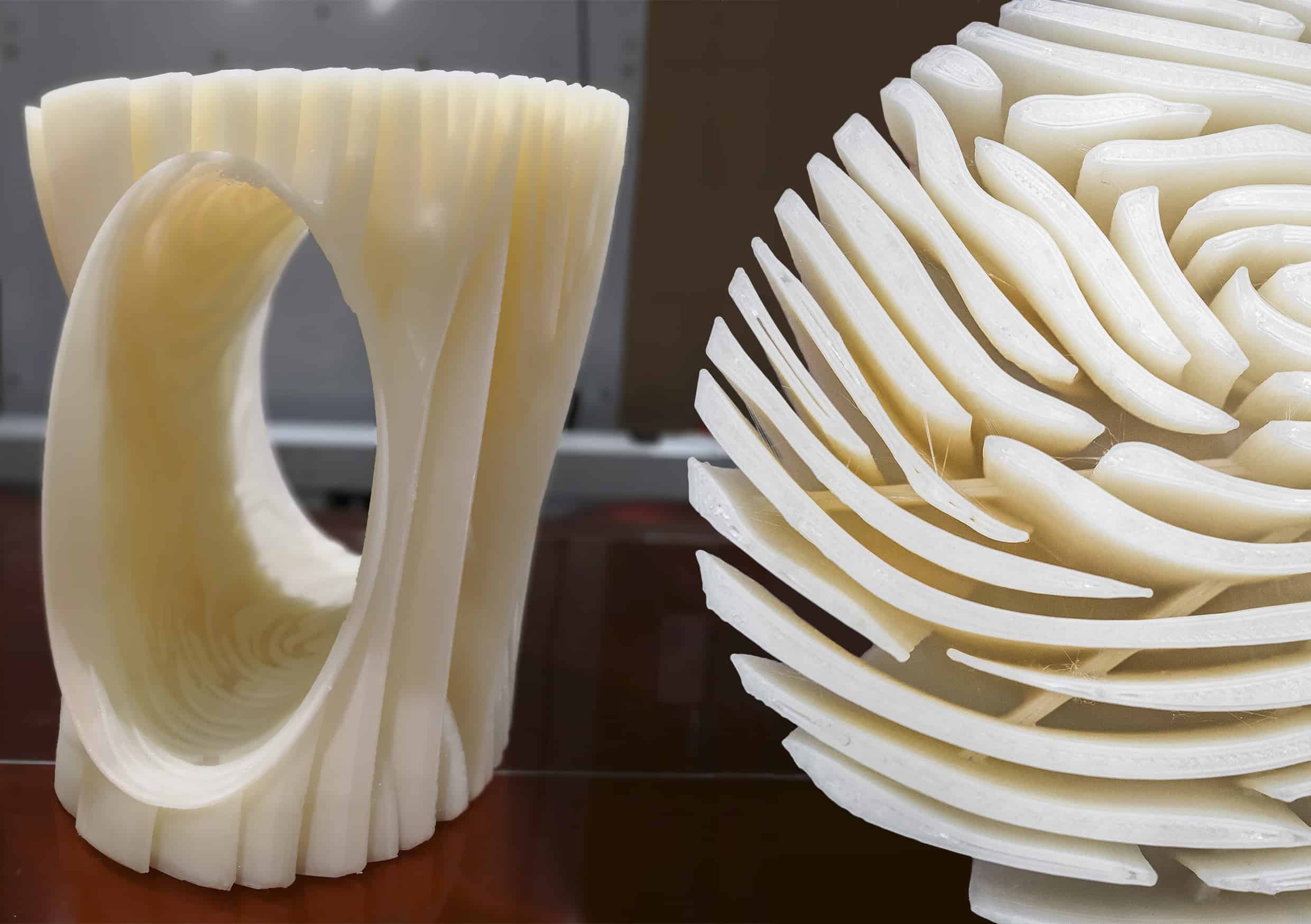

JAMADE started on white paper and progressed through product development. Offering a big 1m3 print volume, the BigRep ONE 3D printer provided unmatched cost efficiency, operational reliability and excellent technical qualities during JAMADE’s prototyping and the end-use parts’ serial production. The material is BigRep’s Pro HT, an easy-to-use filament designed for end-use applications. With a softening resistance of up to 115 °C, it offers a significant increase in temperature resistance (compared to average PLA), and minimal warping and shrinkage, which makes it perfectly suited for marine environments. As a material derived from organic compounds, Pro HT is biodegradable under the correct conditions, CO2 neutral and environmentally friendly.

“This scooter is a BigRep showcase of our digital solutions empowering production by leveraging the full potential of large-format 3D printers with high-performance filaments,” says BigRep Managing Director Martin Back. “It also signifies the rapid progress of 3D printing into the serial production of consumer end products, opening a new dimension for AM in similar niche but high-tech markets as well.”

Find out how industry leaders are using BigRep 3D printers to create affordable and secure investment shipping containers on demand for sensitive aerospace equipment in our case study with Airbus:

Read Now

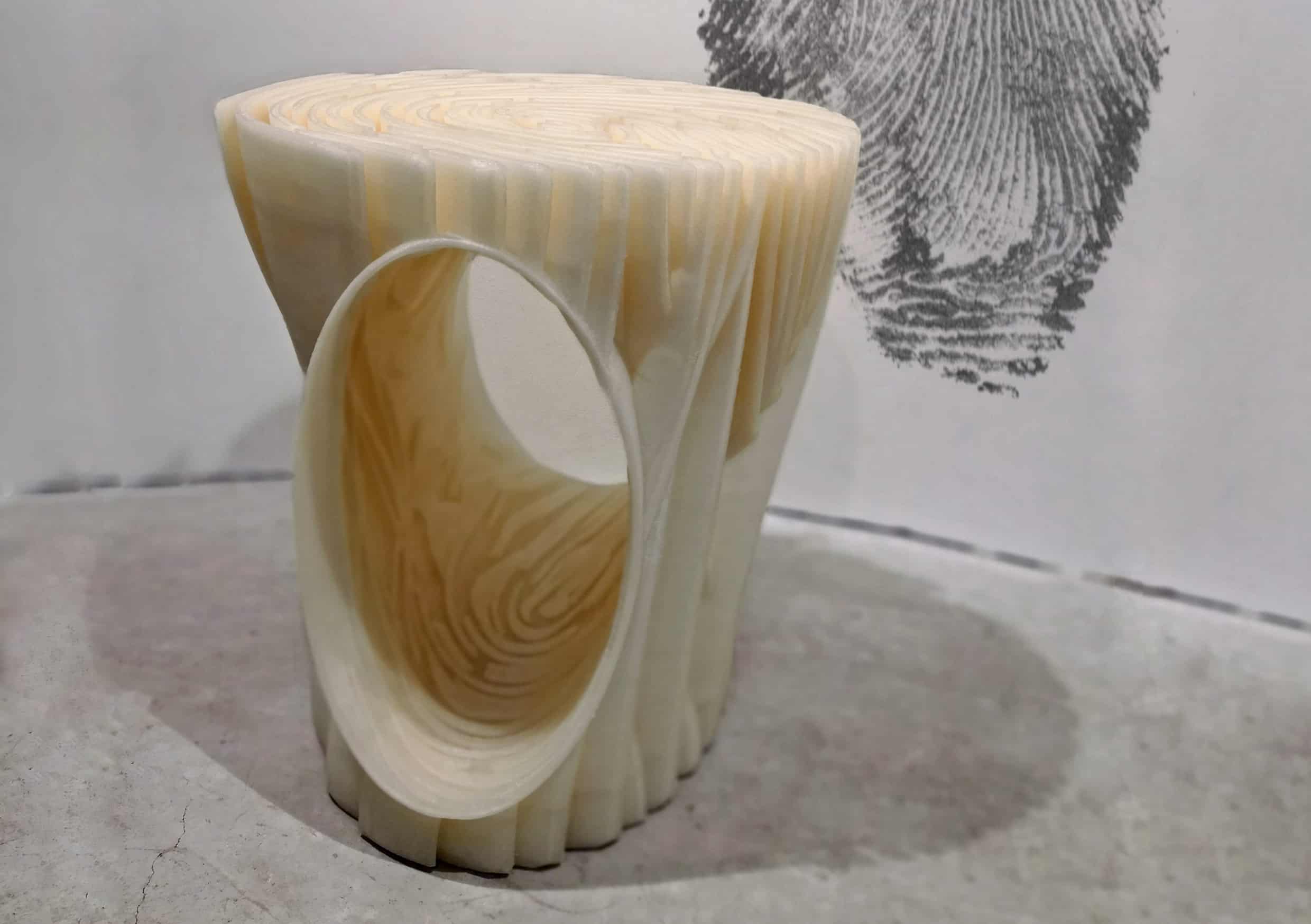

The underwater scooter, which pulls the diver attached to it forward through the water, is an environmentally friendly, emission-free and low-noise method of exploring marine life without disrupting the eco-system. AMAZEA is an agile underwater scooter based on the “catamaran principle” and replicating a dolphin’s special body ergonomics that enable faster movement.

The stylish design offers a robust frame available in various bright colors. Thanks to an electric BI motor drive powered by two engines (3.1 KW each) and a rechargeable lithium-ion battery set up in the scooter’s front, the high-performance scooter offers a maximum speed of 20 km/h (underwater) or 30 km/h (gliding above water) and can be operated up to depths of 18 meters. Thanks to its light weight of just 25 kg (without battery) and a user-friendly control panel, handling is very easy.

3D printing offers real customization. Changes in size or shapes, and customer feedback or requests are able to go straight into the product. Large-format printing also ensures the scooter’s water-resistance: If the front or body were assembled using several smaller parts, openings would be a potential risk for leaks.

Large-format 3D printing enabled the quick turnaround and quality needed for this first of its kind water scooter.