ASA

UV RESISTANCE AND HIGH STRENGTH

MADE FOR

BigRep ASA is a strong, engineering-grade filament that can withstand exposure to the elements thanks to excellent weather and UV resistance. Designed for industrial and end-use parts, ASA is particularly well-suited to applications in automotive and sporting goods where strength and UV stability are crucial. Its superior layer adhesion and low shrinkage mean that ASA 3D prints are less prone to warpage resulting in strong, geometrically accurate parts.

BigRep ASA has been optimized for large-format additive manufacturing and is able to print complex and lightweight ready-to-use parts, including end-use, factory tooling, and functional prototypes. With high heat deflection properties, ASA is well-suited for applications exposing parts to high temperatures and prolonged sunlight.

High Impact

Strength

Weather and UV

Resistance

High Heat Deflection

Temperature

Minimal Shrinkage

for Part Accuracy

Lightweight

3D Prints

Why Use BigRep ASA Filament?

ASA (Acrylonitrile Styrene Acrylate) filament is an engineering-grade thermoplastic known for its high strength, weather resistance, and UV resistance. While bearing similarities to ABS, ASA offers distinct advantages, including superior weather and UV resistance. BigRep ASA filament, optimized for their large-format 3D printers like the STUDIO G2 and PRO, is ideal for outdoor applications such as automotive components, consumer goods, and sporting equipment.

Alongside its UV and weather resistance, ASA filament exhibits excellent impact strength (30 kJ/m²), good heat resistance (up to 86 °C), low shrinkage, and strong layer adhesion. This makes it well-suited for functional prototyping, tooling, and end-use parts, particularly large-scale prints used in outdoor environments. ASA filament provides a material with properties similar to ABS but with superior mechanical properties, aesthetics, and UV resistance, making it a top choice for various applications.

RECOMMENDED APPLICATIONS INCLUDE

Automotive Prototypes

ASA's weather resistance enables testing of functional prototypes of car parts, such as bumpers, grilles, and exterior trim pieces.

End Use Parts

With high strength, weather resistance, UV stability, and chemical resistance, ASA is perfect for durable end-use parts and long-lasting performance.

Jigs & Fixtures

ASA is perfect for producing outdoor fixtures and enclosures, as well as manufacturing jigs requiring durability, accuracy, and chemical resistance.

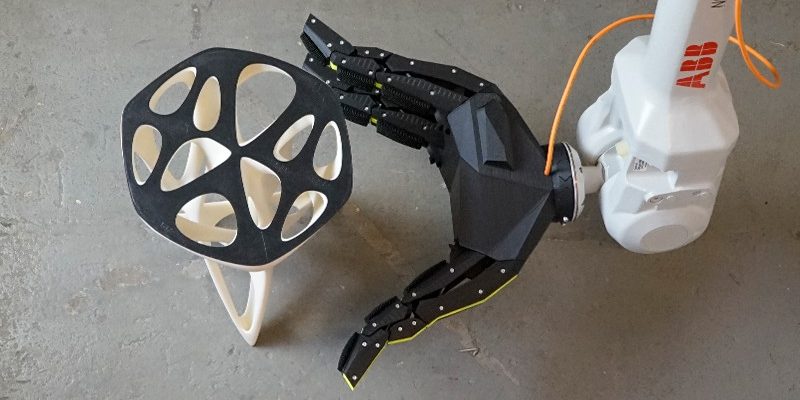

End of Arm Tooling

Durable and chemically resistant, ASA is perfect for producing stable and accurate customized end-of-arm tooling designs.

Outdoor Signage

Ideal for outdoor signage, ASA withstands exposure to sunlight, rain, and other environmental factors while retaining its color and structural integrity.

Sporting Goods

ASA is suitable for sporting goods due to its high strength and resistance to impact. These large-scale prints can withstand the rigors of outdoor activities.

Benefits of 3D Printing BigRep ASA

Among the main benefits of 3D printing BigRep ASA are the material’s high UV stability, impact resistance, and heat resistance. Compared to ABS, ASA filament is also easier to print: it tends to warp less and can be post-processed using mechanical methods like sanding or drilling, as well as chemical smoothing methods, like acetone vapor. When printing ASA, it is possible to achieve high-quality surface finishes that will last through various climates and weather conditions.

In order to unlock the most benefits from BigRep ASA filament and maximize the material’s properties, it’s important to use the right combination of print settings. BigRep recommends the following print temperature and print speed ranges for its ASA material:

Nozzle Temperature

200 - 240 °C

Print Bed Temperature

40 - 80 °C

Print Speed

>40 mm/s

What to Look Out For When 3D Printing BigRep ASA

As we saw, BigRep ASA has numerous benefits, but the material also comes with a couple of challenges. Fortunately, these can be easily overcome by simply adjusting print settings and implementing some print preparation techniques.

The main issue you may encounter when 3D printing ASA filament is warping. Like ABS, ASA is prone to warping on the print bed. This is the result of the printed part cooling too rapidly or unevenly, which causes the material to shrink and pull up from the print surface. The first line of defense against ASA warping is to use a print bed adhesive, such as BigRep Kapton print bed foil and/or Magigoo glue. You can also minimize warping by slowing down the print speed in the first layers of your build. This will help to ensure strong first-layer adhesion as the printer deposits more and more layers.

ASA Material Properties

ASA is known for its high impact resistance and strength. It boasts a higher tensile strength (40 MPa) than standard ABS (30 MPa) with a superior tensile modulus (1900 MPa) than ABS (1400 MPa). Put another way, ASA is more ductile than ABS and can withstand greater stresses without breaking.

In terms of thermal properties, BigRep ASA achieves good heat resistance with an HDT of up to 86 °C. Like ABS, the filament does require relatively high nozzle temperatures for optimal printing results, typically around 215 °C, as well as a heated print bed (40 - 80 °C).

One of ASA’s main selling points is its resistance to UV exposure. In addition to this, the material is also resistant to many chemicals, including certain acids and oils. ASA is also known for its anti-static properties, which make it suitable for electronic applications.

Best Practices for Storing and Handling BigRep ASA

ASA is fairly low maintenance and can easily last upwards of a year under the right conditions: a dark, room-temperature environment that is protected from moisture. A dry environment is important because ASA is moderately hygroscopic, meaning it absorbs moisture from the air. In order to preserve the quality of BigRep ASA spools, you should therefore store the material in a dry room or a sealed container with desiccant. For best results, store ASA in the BigRep SHIELD dry cabinet.

ASA filament does not come with any serious health warnings, but significant exposure to fumes created in the printing process can become hazardous to users. To avoid any potential health risks associated with 3D printing ASA, ensure you are 3D printing in a well-ventilated space. If you are running a 3D print farm or a multi-printer operation, for instance, it’s a good idea to install a local exhaust ventilation system.

Use Cases: See How Customers Use BigRep ASA

BigRep ASA has been enthusiastically adopted by a range of industries, but perhaps none more than automotive. The material’s high strength, as well as its resistance to impact, high temperatures, and weather, have made it a popular option for printing automotive end-use components as well as jigs and fixtures for automotive manufacturing and assembly processes.

Zoeller-Kipper, a specialist in waste disposal technologies, has adopted BigRep 3D printing to produce bespoke modifications for waste disposal vehicles. Thanks to its durability and ability to withstand UV exposure, ASA has been a perfect fit for its needs. In one use case, for example, Zoeller-Kipper 3D printed a large ASA part to be mounted on the rear corner of a garbage truck. The end-use part, which weighed 1,824 grams, was printed on the BigRep PRO and was ready within just two days.

Other uses for ASA in the automotive industry include jigs and fixtures, brackets, mirror housings, and manifolds. Outside automotive, ASA is also a popular material choice for 3D printing electronic enclosures, sporting equipment, parts for the maritime industry, and more.

Physical properties:

| Material: | Acrylonnitrile Styrene Acrylatel |

| Filament Sizes: | 2.3, 4.5 and 8.0 kg |

| Diameter: | 2.85 mm |

| Density: | 1.08 g/cm³ |

| Flexural Modulus (ISO 178): | 1250 MPa |

| Tensile Strength (ISO 527): | 40 MPa |

| Tensile Modulus (ATM D638): | 1900 MPa |

| Impact Strength, notched (ISO 179): | 30 kJ/m³ |

| HDT / B (ISO 750): | 86 °C |

Recommended printing conditions:

| Nozzle Temperature: | 200 - 240 °C |

| Print Bed Temperature: | 40 - 80 °C |

| Environmental Temperature: | n.a. |

| Printing Speed: | > 40 mm/s |

Additional comment: To ensure constant material properties and printability the filament should always be kept dry.