BLADE 3.5.0

Update to Cura 4.12 Improved UI Better surfaces by using monotonic ordering Faster startup times Speed management Speed is now calculated during the slicing process and dynamically adapted based on the (non-fixed) line width and layer height Speed values were replaced with upper speed limits, which do not take into account extruder flow rate limits … Read more

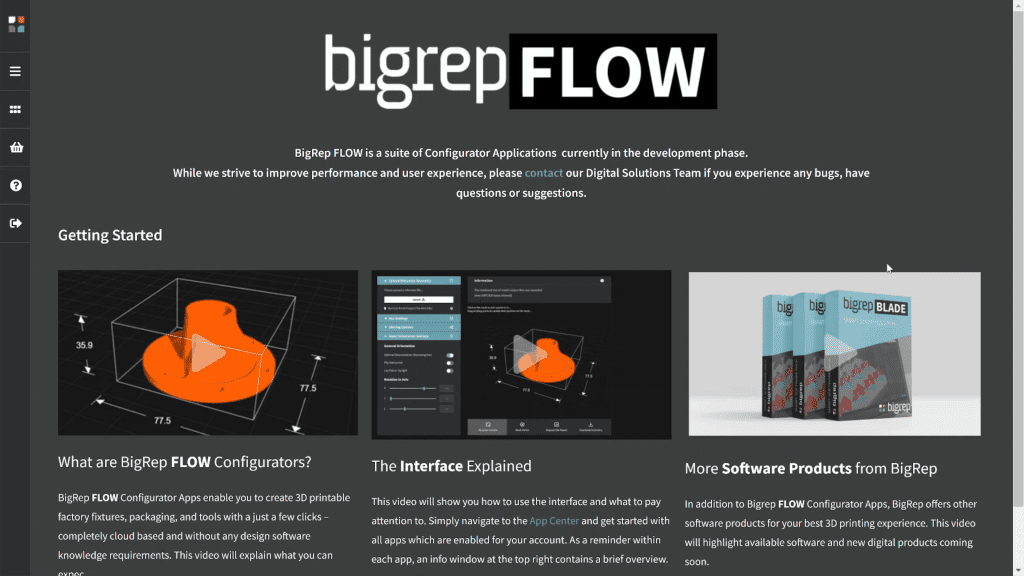

BigRep Introduces BigRep FLOW, an End-to-End Solution for Production Aids

BigRep FLOW is a new customizable SaaS solution that makes application engineering for 3D printed jigs, fixtures, and manufacturing aids easier than ever, with no design skills or 3D printing experience required.

A Short Introduction to Generative Design

Imagine you could create thousands of options for a single design the push of a button and then you just pick the best option! Generative design makes this possible.

7 Considerations for Purchasing an Industrial 3D Printer

There are several factors to consider before buying a large format industrial 3D printer. In this blog we evaluate the top 7 aspects such as your application, part usage, the material requirements, software, and budget.

BLADE 3.4.2

Added One.4 with the following material profiles for PEX FR 1mm and PEX FR 0.6mm: Pro HT HI-TEMP HI-TEMP-CF PLX BVOH PLA Added PRO.2 with the same material profiles as PRO.1 Renamed Printers ONEv3->ONE.3, STUDIO G2->STUDIO.2, PRO 1.1->PRO.1 Activated FW 2.0 for PRO.1. A patch is not needed anymore. Though a patch is needed now … Read more