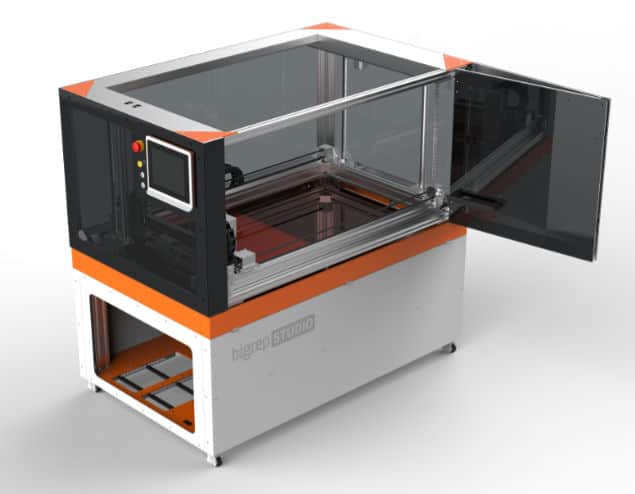

To create something truly original, sometimes you must throw the rulebook out the window. Berlin-based artist Lindsay Lawson knows all about challenging the boundaries of what is possible, especially when it comes to technology – in fact, it’s an essential facet of her work creating sculpture and other artworks for 3D printing. Lindsay has had her works exhibited extensively across Europe and the United States, where she is originally from. When she is not exhibiting in cities like Vienna, Los Angeles, London or Rome, Lindsay works with BigRep on special projects that challenge its large-scale printers to develop interesting and complex 3D-printed objects.

It was Lindsay’s experience raising artistic works from the 3D print bed, fusing form and function, that made her a clear choice for the jury in the BigRep Innovation Award’s open call to students in Canada. As part of the four-person jury, Lindsay will help decide the ultimate winner of a Canada-wide competition, with a $3,000 cash prize, for the most innovative design of a 3D-printed chair. Following a public vote, a select number of entrants’ designs will be presented to the jury members, who will all be looking for originality, strong understanding of 3D printing principles, aesthetic innovation and structural integrity.

We sat down with Lindsay to find out how she approaches 3D printing in her work, and get her tips for competition entrants.

BigRep: Could you please tell us a bit about how and why you developed your expertise in 3D printing as an artist?

Lindsay Lawson: My artistic practice is centered around sculpture and video. While my initial foray into 3D modelling was animation, I soon wanted to translate those skills into 3D printed sculptures. Any type of art-making is somehow affected by the tools and materials one chooses to use. With 3D printing the process is how to turn a virtual form into a physical object, and that opens up many new paths to creating something interesting.

BR: With your use of 3D printing technology in your work, how do you balance form + aesthetic with function + structure? What are the challenges you encounter in striking this balance?

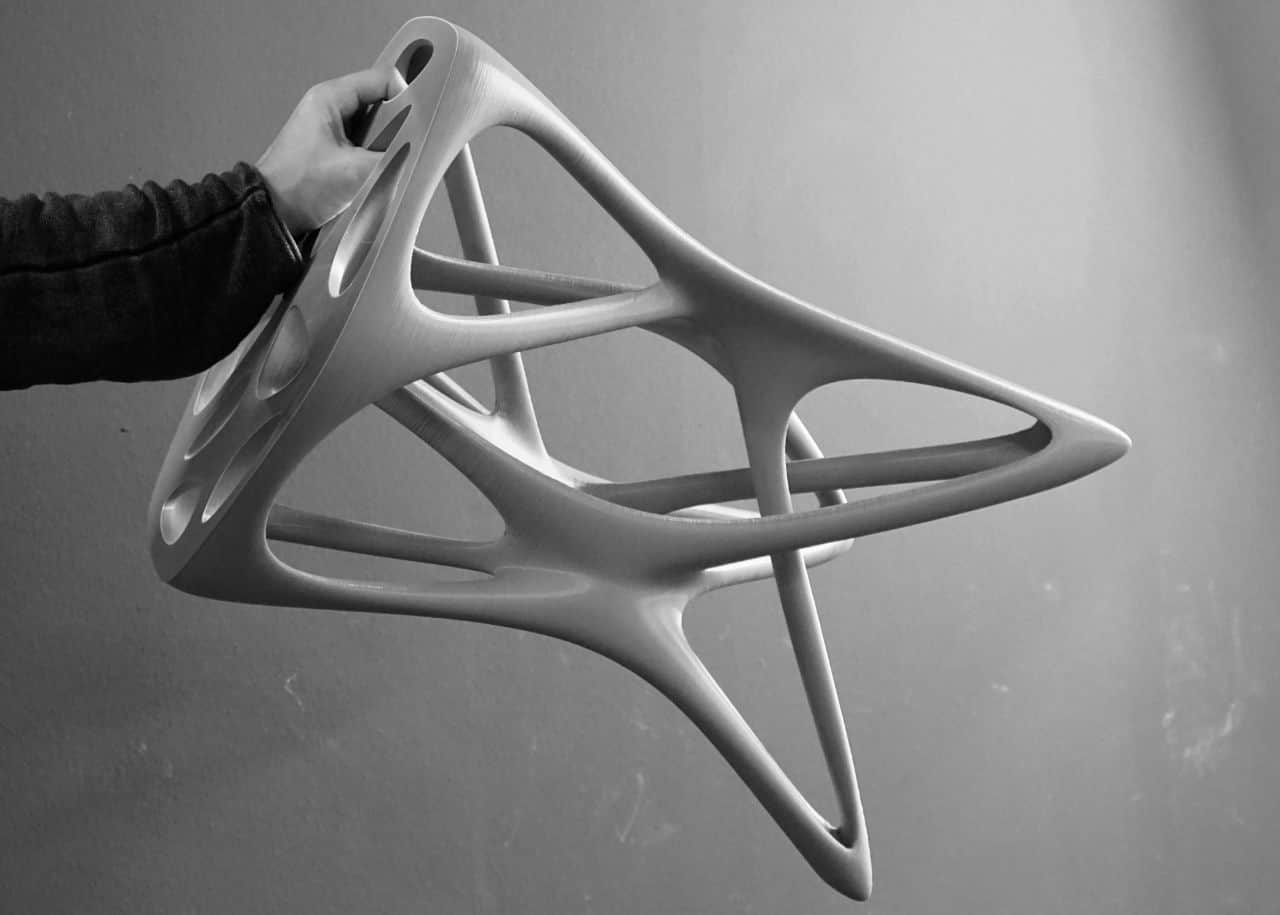

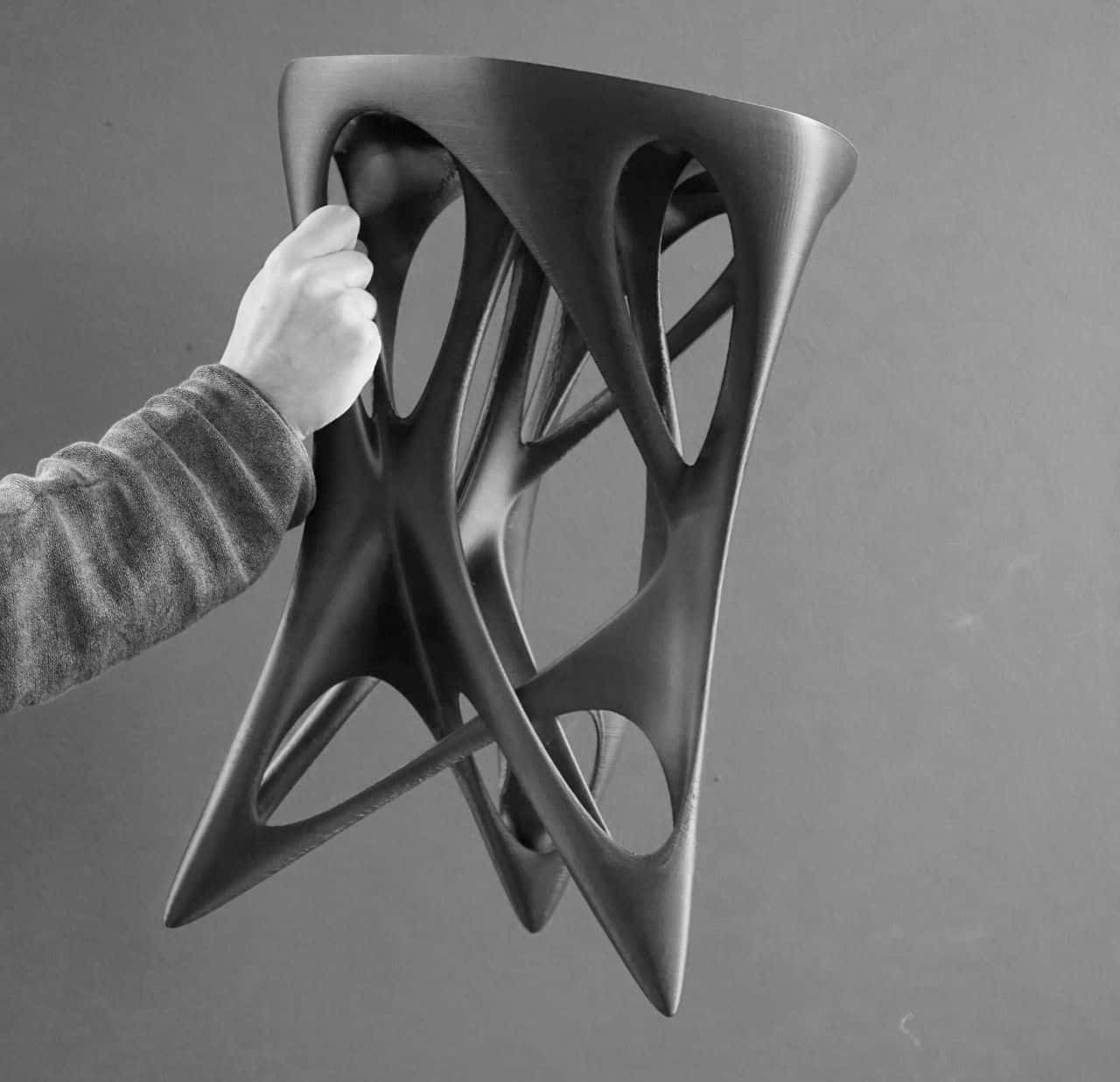

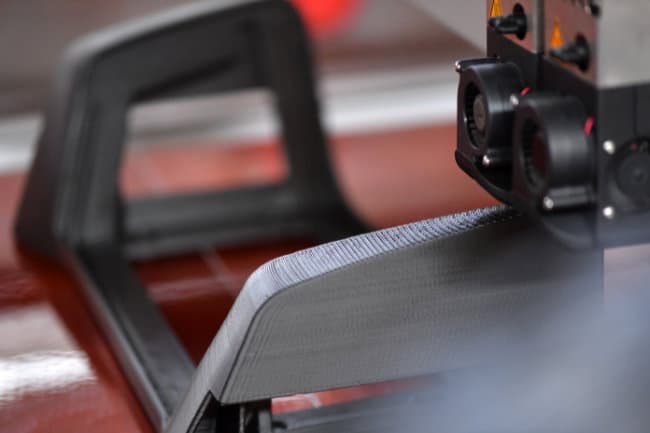

LL: The key is to design objects that are particularly suited for additive manufacturing, otherwise it’s like eating soup with a fork. I’m all about printing fast and light so I like to design objects that require no support with minimal infill and few perimeters. Often this means bending some rules of 3D printing – for example, sometimes I like to over-extrude so that I get a thicker wall on a single perimeter print rather than making it double perimeter, therefore cutting the print time in half. But if you’re going to break some rules it’s crucial to design intelligently for the technology you’re using, rather than working against it.

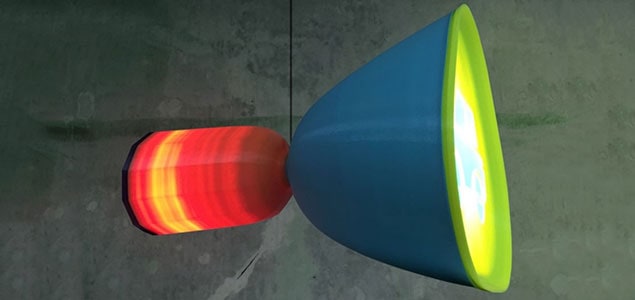

I particularly like to work with some of our more challenging 3D printer materials like transparent PETG, wood filament, flexible TPU. By “challenging” I mean that these materials may not print certain geometries as well as standard materials like PLA. I recently designed some light fixtures that were printed with transparent PETG because the material has a beautiful, silver luster when it refracts light. That project required that I first consider the limitations of FFF in addition to the printability of PETG to inform the functional design of the structure. For me, aesthetic decisions always come last.

BR: Do you have any words of advice to any students for whom the Innovation Award is their first official design award submission?

LL: If you want to 3D print an object, there is no point in designing something beautiful that can’t be printed. My biggest advice for Innovation Award submissions would be to understand how FFF works and then use the constraints of the technology as a starting point for inspiration.

BR: Which news sources, blogs or publications do you devour for inspiration and industry news?

LL: Since my background is in art, I pay a lot of attention to contemporary art publications and exhibitions, but for design inspiration I like to look at Dezeen and designboom. There are many innovators here at BigRep, so I get a lot of industry news shared from curious colleagues.

Read more here from two other BigRep Innovation Award jury members about their approach to designing furniture for 3D printing. Full competition details, including the entry form, can be found here.

Lindsay Lawson is an artist and a 3D printing specialist, NOWLab @ BigRep