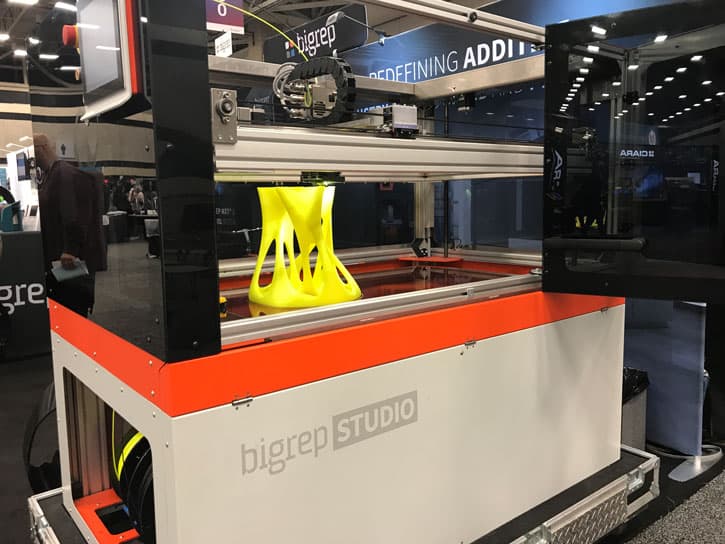

Powered by BigRep MXT® and state-of-the-art CNC control systems and drives by Bosch Rexroth, the PRO delivers unprecedented speed, precision and quality for industrial applications and full connectivity to integrate additive manufacturing with Industry 4.0.

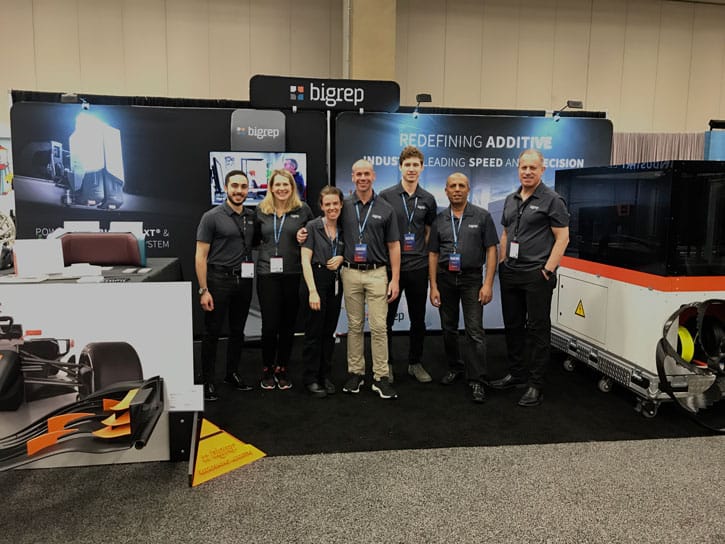

Chicago, IL, March 27, 2019 - BigRep, the global leader in large-scale 3D printing, will debut its highly anticipated all new PRO at AMUG (Additive Manufacturing User Group) Conference in Chicago (March 31 – April 4, 2019). For the first time in North America, attendees from various industries can experience the PRO. Equipped with BigRep’s new MXT®, an exclusive Metering Extruder Technology, and a state-of-the-art Bosch Rexroth motion control system, the PRO delivers unprecedented speed, precision, quality and IoT connectivity that fully integrates with Industry 4.0. The PRO can be ordered now.

During AMUG, BigRep will offer two exciting presentations in partnership with industry experts. During the first session “Speed, Precision and Connectivity for Factory 4.0”, BigRep and Bosch Rexroth will team up to share their vision for the factory of the future, the vital role that additive will play and how to fully connect 3D printing into a manufacturing process. The second presentation “How Large-Scale Additive is Transforming Industries” will feature experts from Boyce Technologies and Ford Motor Company, as they share case studies for prototyping, tooling, patterns/molds and end-use parts. The experts will also discuss the added value for manufacturers and how and why leading companies are integrating AM into their production strategies.

“We are proud and excited to have our partner, Bosch Rexroth, and customers, Boyce Technologies and Ford, join us at AMUG to share their expert insights on the value and future of additive manufacturing,” said BigRep CBO, Frank Marangell. “Our latest technology offers customers complete solutions for integrated additive manufacturing systems, enabling companies to reimagine how they produce parts from design to production.”

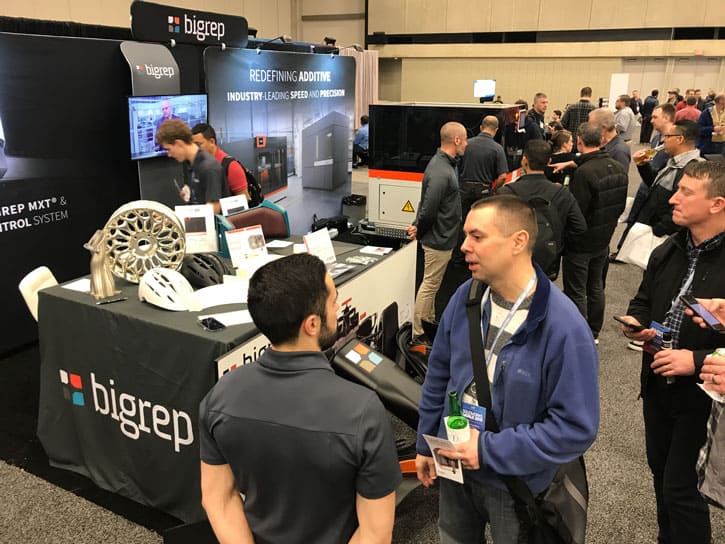

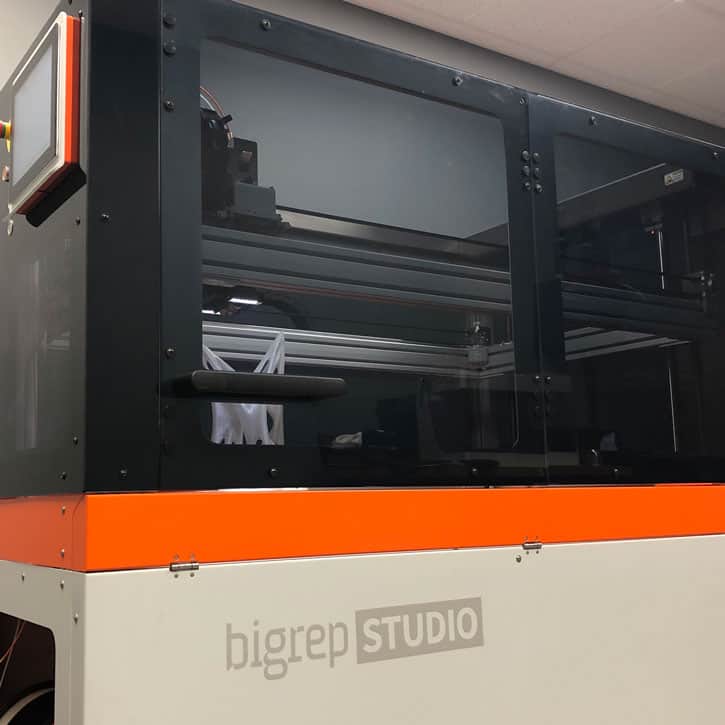

All throughout AMUG, BigRep will be conducting live demonstrations of the PRO. During the demo, attendees will get to see up close the PRO’s one cubic meter build envelope and large, temperature-controlled spool chamber allowing for continuous printing with high-performance materials. Plus learn more about the software and state-of-the-art technology powering the PRO including the new CNC control systems and drives by Bosch Rexroth and BigRep MXT®.

“Our new groundbreaking MXT® system is something the industry has been waiting for, as it makes the PRO five times faster with greater precision and quality than current extrusion speeds,” said BigRep CEO, Stephan Beyer, PhD. “And AMUG, which encompasses a wealth of additive knowledge and industry leaders, is the perfect place to introduce the PRO to the North American market and demonstrate its full performance capabilities.”

BigRep events at AMUG at a glance:

BigRep presentations

- Tuesday, April 2 from 1:30 – 2:30 pm (Wilford A/B), “Speed, Precision and Connectivity for Factory 4.0” by Stephan Beyer, PhD, BigRep CEO, and Karl Rapp, Bosch Rexroth.

- Thursday, April 4 from 3 – 4 pm (Wilford C), “How Large-Scale Additive is Transforming Industries” by Frank Marangell, BigRep CBO, Ajmal Aqtash, Boyce Technologies, and Lars Bognar, Ford Motor Company.

Live BigRep PRO demonstrations in salon C, room 3

- Monday, April 1 from 3 to 4 pm

- Wednesday, April 3 from 1:30 to 2:30 pm

- And upon request

About BigRep:

BigRep develops the world’s largest serial production 3D printers, creating the industry benchmark for large-scale printing with the aim to reshape manufacturing. Its award-winning, German-engineered machines are establishing new standards in speed, reliability and efficiency. BigRep’s printers are the preferred choice of engineers, designers and manufacturers at leading companies in the industrial, automotive and aerospace sectors. Through collaborations with its strategic partners – including Bosch Rexroth, Etihad Airways and Deutsche Bahn – and key investors – including BASF, Koehler, Klöckner and Körber – BigRep continues to develop complete solutions for integrated additive manufacturing systems, as well as a wide range of printing materials on an open-choice source. Founded in 2014, BigRep is headquartered in Berlin with offices in Boston and Singapore. Leading the way in one of the world’s key technologies, our multinational engineering teams are highly trained, interdisciplinary and customer-focused.

For more information on BigRep and its solutions and to arrange an interview with BigRep CEO, Stephan Beyer, PhD, or BigRep CBO, Frank Marangell, and, please contact:

Juergen Scheunemann

PR & Communication

PR & Communications BigRep GmbH

T +49 30 9487 1430

E [email protected]

Abbey Delaney

North American Marketing Manager BigRep

M (989) 860 – 8210

E [email protected]