3D Printing Applications

Industrial 3D printing offers a fast, cost-effective avenue to build and streamline processes in real-world applications.

Prototyping, production tooling, and manufacturing processes are all simplified with industrial additive manufacturing technology. Add large-format 3D printers into your company workflows to reduce production costs and time-to-market, and develop sustainable practices that enable complete control throughout your product's entire life cycle.

Application Guides

Aerospace Maintenance, Repair, and Overhaul (MRO)

- Minimize logistics and produce in weeks, not months

- Cut costs for custom and low-volume production

- Improve MRO performance with easy iteration and custom complex parts

3D Printed Jigs & Fixtures on the Factory Floor

- Minimize logistics by manufacturing jigs and fixtures in-house

- Cut tooling costs with digitized production and reduced assembly

- Print tools on demand from a digital inventory to save time and storage space

Carbon Fiber Parts with 3D Printed Molds

- 3D printing molds costs a fraction of the price of CNC milling aluminum

- Drastically reduce lead times and speed up design iterations

- Adapt, test, and produce parts in-house with ease

Concrete Casting with 3D Printed Formwork

- Produce complex formwork at lightning speed with reduced lead times

- Save money with reduced costs of digital craftsmanship

- Achieve complex shapes unthinkable with traditional methods

Sand Casting with 3D Printed Patterns

- Speed up fabrication and reduce lead times

- Cut costs with fast and precise digital workflows

- Streamline workflows and ramp up production

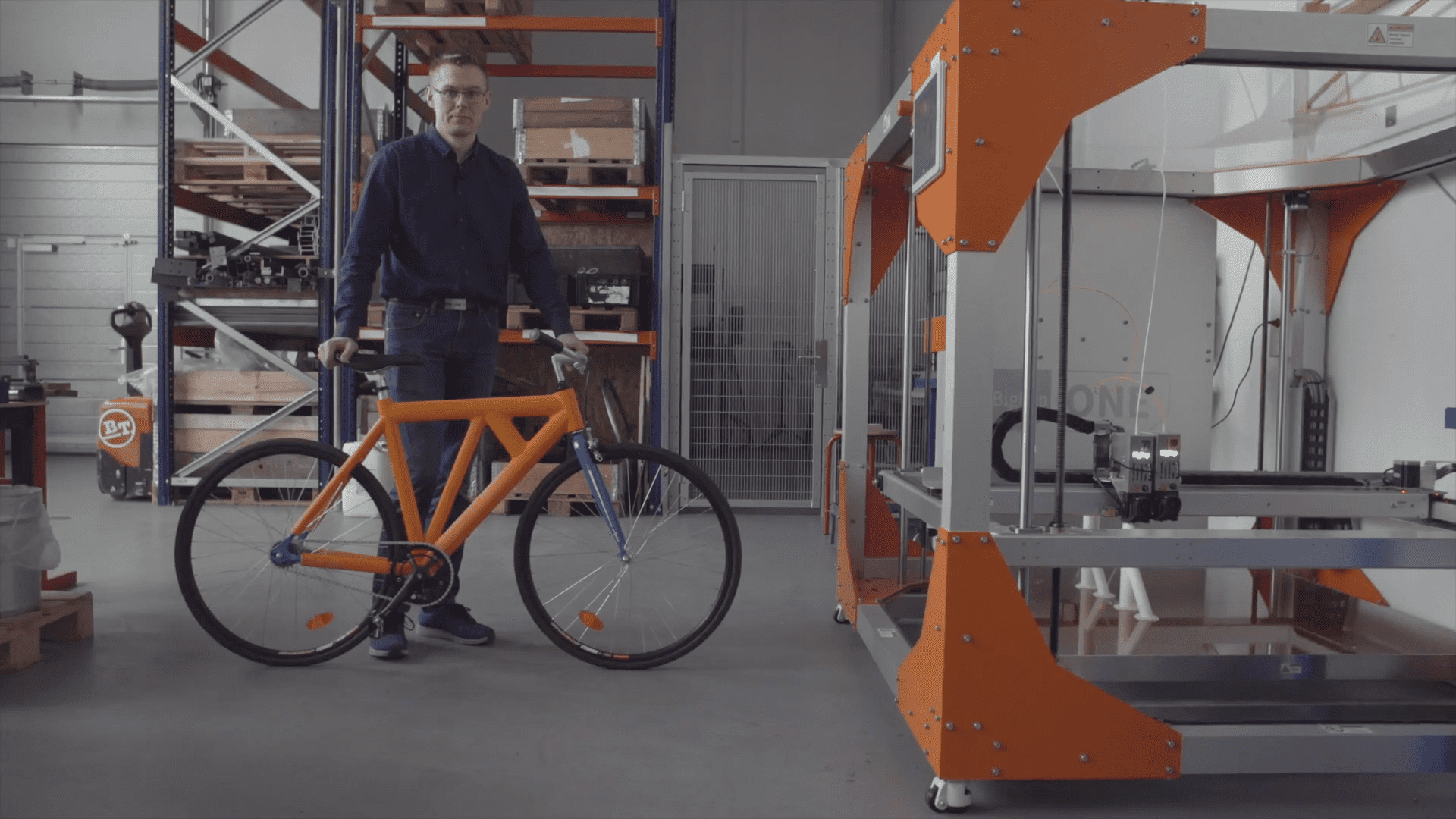

Electric Vehicles with 3D Printed Prototypes and Tooling

- Reduce lead times, avoid outsourcing, and save time with streamlined processes

- Bypass expensive machining by directly printing end-use parts and low-cost patterns

- Leave conventional ways of development and manufacturing behind to design and produce smarter

Vehicle Customization with 3D Printed Parts and Patterns

- Reduce lead times, avoid outsourcing, and save time with streamlined processes

- Bypass expensive machining by directly printing end-use parts and low-cost patterns

- Produce on demand without added costs and avoid the cost and uncertainty of keeping stock parts

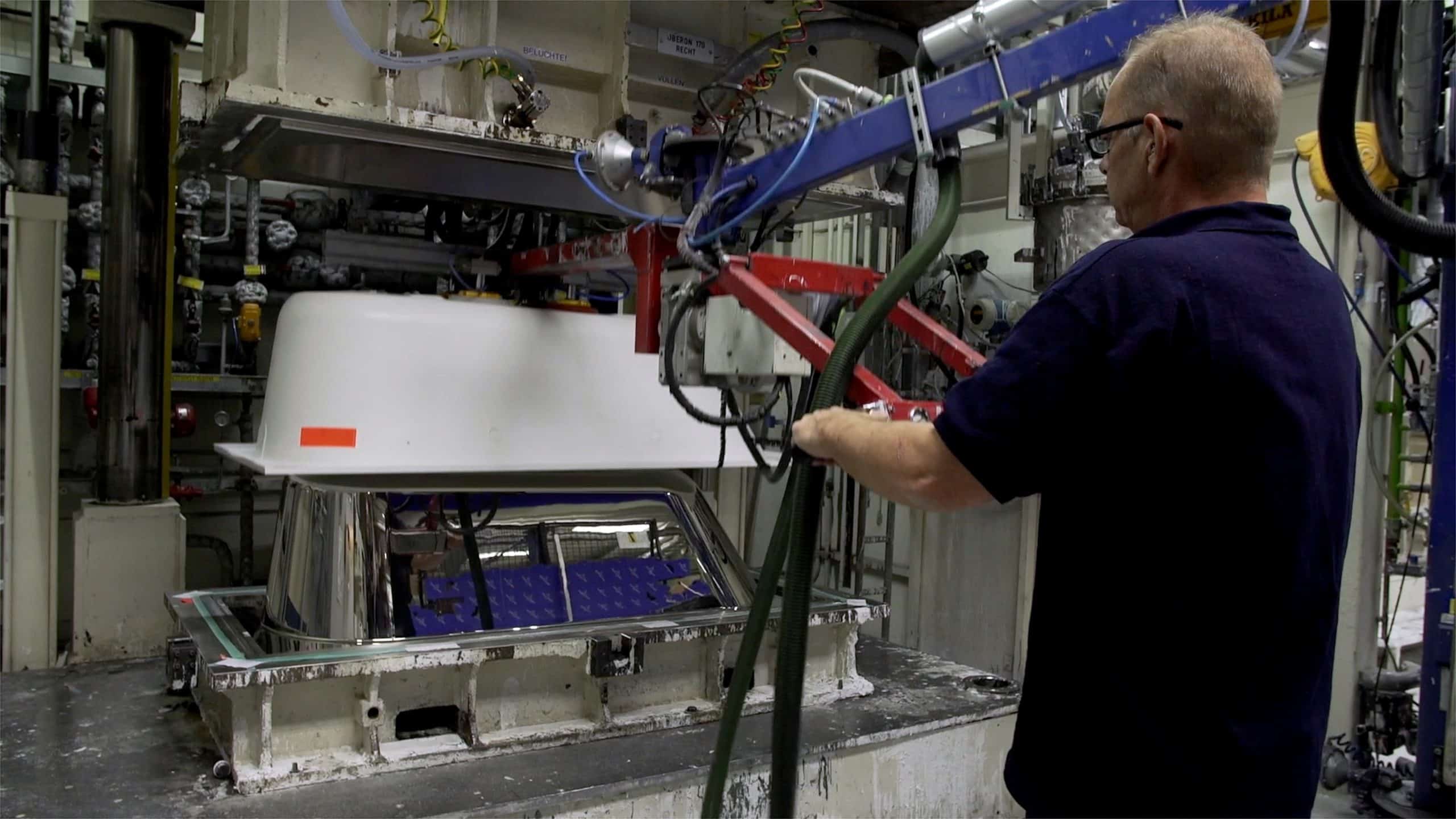

Trucks Customization with 3D Printed Parts and Tools

- Reduce lead times, avoid outsourcing, cut logistics, and save time with streamlined processes

- Bypass expensive machining or injection molding by directly printing prototypes, end-use parts, and tools

- Leave conventional ways of manufacturing behind and take the chance to design smarter

Design Prototypes for Industrial Production

- Prototyping design iterations is faster and easier as part of a seamless digital workflow

- Get better-informed feedback regarding part fit, function, aesthetics, and more with full-scale prototypes

- Accelerate time to market with 3D printed prototypes produced in a fraction of the time

3D Printing for Universities and Research Institutes

- Provide researchers and scientists with the right tools and methods to invent and prototype much faster

- Create new methods to impart knowledge and reimagine the way students learn

- Enable students to think more creatively by freeing them from the restrictions of traditional processes

Unlimited Creativity in 3D Printed Exhibitions

- Your imagination is the only limit to what you can create with a 1m3 building volume of BigRep 3D printers

- Keep on schedule to manage tight deadlines by avoiding manual labor and outsourcing

- 3D printing can reduce costly material waste and replace expensive skilled labor

General 3D Printing Applications

Rapid Prototyping

Reduce Cost and Lead Time with Industrial 3D Printing in Product Development.

Rapid Manufacturing

Take Control of Your Manufacturing with Industrial 3D Printing for End-Use Parts.

Rapid Tooling

Develop Solutions On-Demand with Industrial 3D Printing for Jigs and Fixtures.

Forms & Moulding

Create Patterns Affordably with Industrial 3D Printing for Forms and Moulding.