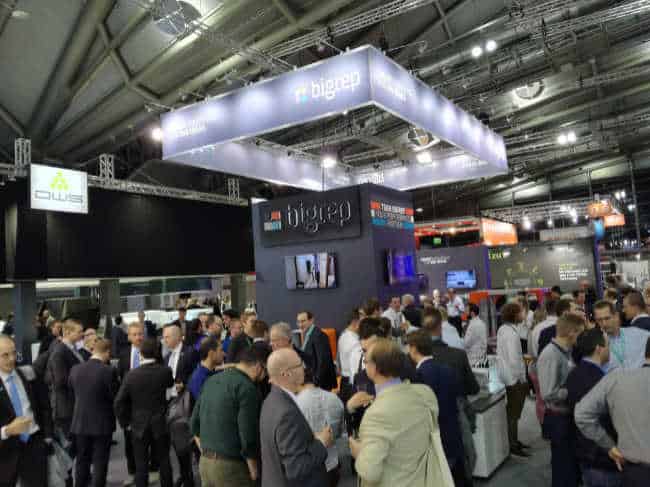

Formnext 2017 was another great event for industrial 3D printer enthusiasts. More companies have joined the race to bring 3D print technology to maturity and we saw plenty of new products on offer. Overall, a clear message came across – that additive manufacturing is here to stay and will continue to dramatically change the way we design and manufacture products.

Before discussing which technology and/or company is most likely to lead the industrial 3D printer market in coming years, we will investigate two key areas – 3D print solutions for prototyping and for manufacturing.

3D PRINTERS FOR PROTOTYPES

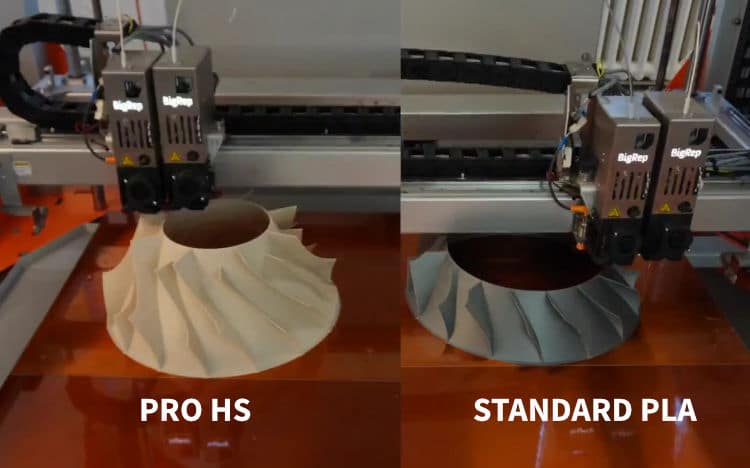

Within this segment of the market affordable 3D printers for plastic prototyping are making headway. These are not necessarily cheap 3D printers, but machines which strike a lower-cost balance between functionality and price. In the past such machines had few features and competed mainly on price. At Formnext 2017 we saw more sophisticated machines which can be used for specific applications such as dental and other fit-form-function applications. This means that higher-cost machines dedicated to prototyping must offer unique features to be attractive. BigRep offers industry exactly this kind of added-value through its large-scale industrial 3D printers and growing range of specialist 3D printer filaments.

3D PRINTERS FOR MANUFACTURING

3D printing for manufacturing can be divided into two areas – plastic and metal 3D printing. With plastic, advanced polymers can replace metal for certain applications in Medical, Aerospace and other industries. In such cases if superior mechanical properties and/or larger parts can be delivered we have a more attractive solution. If printing speeds increase, plastic 3D printing could also potentially replace injection molding in some manufacturing applications.

The second manufacturing area, metal 3D printing made a big splash at Formnext 2017. On the one hand the prices of some lower-spec machines seem to be falling, making metal 3D printers more accessible. At the same time, new heavy metal printers are aiming to deepen the automation and integration of 3D printing in manufacturing processes with a focus on quality, variety of materials and printing speed.

LOOKING FORWARD – WHAT WILL BE THE NAME OF THE INDUSTRIAL 3D PRINTER GAME?

If we look at it from the industrial user’s side, before purchasing a 3D printer the following elements are usually considered:

- The company behind the product – is it a short or long-term player?

- Quality, accuracy & repeatability – the basics of effective additive manufacturing

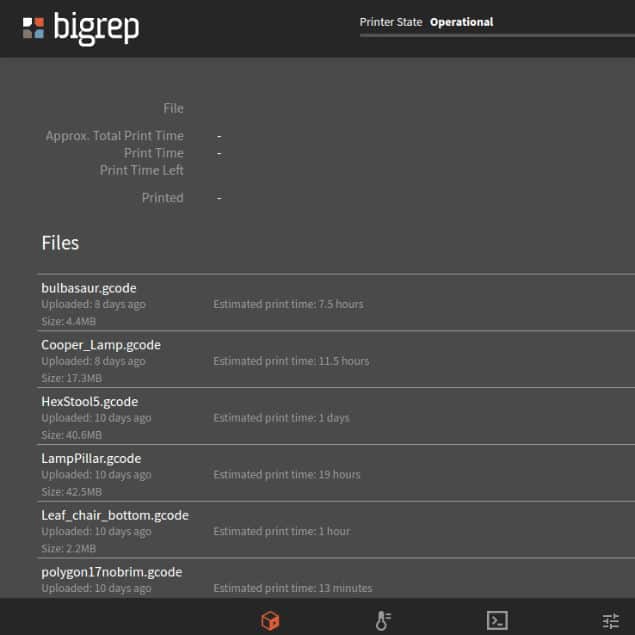

- Reliability & ease of use – for minimum hassle

- Variety of materials - for a wide range of applications

- ECO system - inclusion of a dedicated Software solution. This is particularly critical in the metal printing space

- Printing speed – this must increase to increase productivity, especially in manufacturing

- Reasonable cost per value – an essential requirement of the end user

SO WHICH COMPANY AND/OR TECHNOLOGY HAS THE POTENTIAL TO LEAD THIS INDUSTRY?

It depends on how you measure it, but no doubt a strong combination of a ‘new generation’ technology with a focus on printing speed and advanced materials, plentiful long-term funding, and a winning business strategy will be key success factors for any 3D printer company. Above all one factor will be most important – the people behind the company. Without a professional, experienced, and totally dedicated team driving it forward, any new amazing technology cannot make it. At Formnext 2018 we will see who and which technologies are making the best progress.

All parts below were printed with BigRep Large Scale 3D-Printing Technology

With over 22 years in the printing industry, Gil Lavi is a Sr. 3D-Printing Specialist with vast experience in implementing diverse 3D-printing technologies in design and manufacturing processes.

Connect with Gil on Linkedin HERE.