PLX

COST EFFECTIVE AND RELIABLE

AVAILABLE COLORS

BigRep's PLX filament is optimized for large-format 3D printers and consistently delivers high-quality parts at an attractive price. Particularly easy to print, PLX achieves beautiful print surfaces on even the most demanding geometries.

PLX is incredibly versatile, allowing printer settings to be tuned for either higher speeds or beautifully smooth surface finishes. PLX delivers consistent results that make it a reliable material for large-format printing in any industry. Given its balanced performance under various mechanical stresses, PLX is a great all-around filament choice.

As a PLA-based material derived from organic compounds, PLX is biodegradable under the correct conditions. CO2 neutral and environmentally friendly, it has a much lower ecological impact than other plastics derived from fossil fuels.

MADE FOR

Easy to Print for

Wide Range of Uses

More Affordable for

Cost Savings

Highly Consistent

Print Results

Beautiful Surface

Quality

Reduced

Environmental Impact

What is PLX 3D Printing Filament?

PLX is a PLA-based filament that combines the benefits of PLA—such as easy printability—with enhanced properties. Specifically, PLX has been engineered by BigRep to deliver superior strength and performance compared to PLA, and can be printed up to 80% faster. Like BigRep PLA, PLX is derived from organic compounds and is biodegradable when disposed of in the right conditions.

BigRep has fine-tuned PLX filament for its large-format 3D printing platforms, ensuring that no matter the scale of a part, the filament will maintain good printability, adhesion, and surface quality. The filament is also compatible with other FFF platforms. In general, PLX is considered an affordable, versatile material that brings consistency and high print quality to the table.

Why Use BigRep PLX Filament?

Users looking for a material that combines the printability of PLA with mechanical properties that rival (and can even exceed) ABS should consider BigRep PLX. The general use filament is well suited to many types of application, from design models and functional prototypes, to tooling, to aesthetic end-use parts.

Engineered for printing speeds of up to 120 mm/s, PLX unlocks faster print times, which can accelerate product development timelines significantly. The material can also be printed at lower print speeds to achieve excellent print surface quality, even for fine details. The material thus has many possible uses, and—thanks to its affordable price point—is accessible to a wide range of different adopters, from hobbyists to industrial users.

PROTOTYPES

MOLDING

EXHIBITIONS

TOOLING

Benefits of 3D Printing BigRep PLX

As we’ve seen, one of the primary benefits of BigRep PLX is its print speed. The material can be processed at speeds up to 80% faster than classic PLA, which offers big advantages to those working with tight schedules and turnaround times. But print speed is only part of the equation: with the right print settings, PLX prints can also achieve exceptional surface finishes.

On top of that, PLX is known for being user friendly. Similar to PLA, the material does not require extreme print temperatures, it demonstrates good bed adhesion, and is resistant to warping. Users have also noted that support removal (either soluble BVOH or breakaway supports) for PLX prints is painless. Another big benefit of working with PLX is that the material is manufactured from renewable resources and can be biodegraded. This gives the filament a distinct environmental advantage compared to plastics derived from non-renewable resources like petroleum.

In order to unlock the most benefits from BigRep PLX filament and maximize the material’s properties, it’s important to use the right combination of print settings.

RECOMMENDED PRINT SETTINGS

- Nozzle temperature: 190 - 220 °C

- Print Bed Temperature: 50 - 70 °C

- Chamber Temperature: n/a

- Print Speed: 40-120 mm/s

PLX filament has a slightly lower tensile strength than BigRep PLA (48 MPa vs 60 MPa), however the material makes up for that with significantly higher ductility. Whereas BigRep PLA has only 4% elongation at break, PLX has an elongation at break of 20%. PLX also has superior flexural strength and impact strength than PLA.

When it comes to thermal properties, PLX has a slight edge over PLA. While PLA has a heat deflection temperature of up to 60 °C, PLX boasts a glass transition temperature of 63 °C and HDT of up to 68 °C. This approaches that of BigRep PETG (70 °C) , though is still substantially lower than ABS (91 °C).

As a polylactic acid blend, PLX has similar chemical properties to its sister filament PLA. In general, these filaments are not known for their resistance to chemicals, including common post-processing solvents like acetone, as well as acids, and alcohols. It’s also worth remembering that PLX can degrade when exposed to UV rays.

What to Look Out for When 3D Printing BigRep PLX

In general, there aren’t many caveats when 3D printing BigRep PLX. The material is easy to use, works with a wide range of FFF 3D printers, and delivers good print results, even at fast print speeds.

One factor that bears keeping in mind, however, is heat resistance. Like PLA, PLX is not a high-temperature filament. On the one hand, this is a good thing: the material can print at relatively low temperatures and does not require an enclosed build environment. On the other hand, with a heat deflection temperature (HDT) of 68 °C, PLX is not particularly well suited to applications that are exposed to extreme temperatures. The filament is also not UV resistant, which limits outdoor applications.

Best Practices for Storing and Handling BigRep PLX

When 3D printing PLX, proper storage and handling are critical to unlocking the best print results. Fortunately for users, the filament is relatively low maintenance, needing simply to be stored in a dry, room-temperature environment away from the sun. While not the most prone to moisture absorption, PLX is still considered slightly hygroscopic, hence the dry environment.

If a spool of PLX is exposed to humidity, it is possible to dry it out before printing. BigRep recommends baking the filament at no more than 50 °C for 4 to 6 hours. For industrial users, the BigRep SHIELD, a filament dry cabinet capable of storing up to 60 kg of filament spools, can extend the shelf life and quality of PLX filament.

It is also important to maintain good ventilation when using PLX (and any other filament) to disperse fumes and vapors generated in the extrusion process. Finally, BigRep recommends wearing personal protective equipment, like gloves, a mask, and eyewear, while post-processing PLX prints.

Use Cases: See How Customers Use BigRep PLX

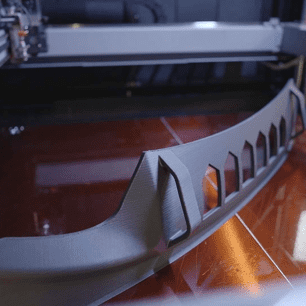

Fast-printing PLX filament is a good candidate for many of the same applications as PLA, such as prototypes and large-scale models with excellent aesthetic quality. The material also has viability for a number of industrial applications, including tooling for aircraft maintenance parts. Let’s take a closer look.

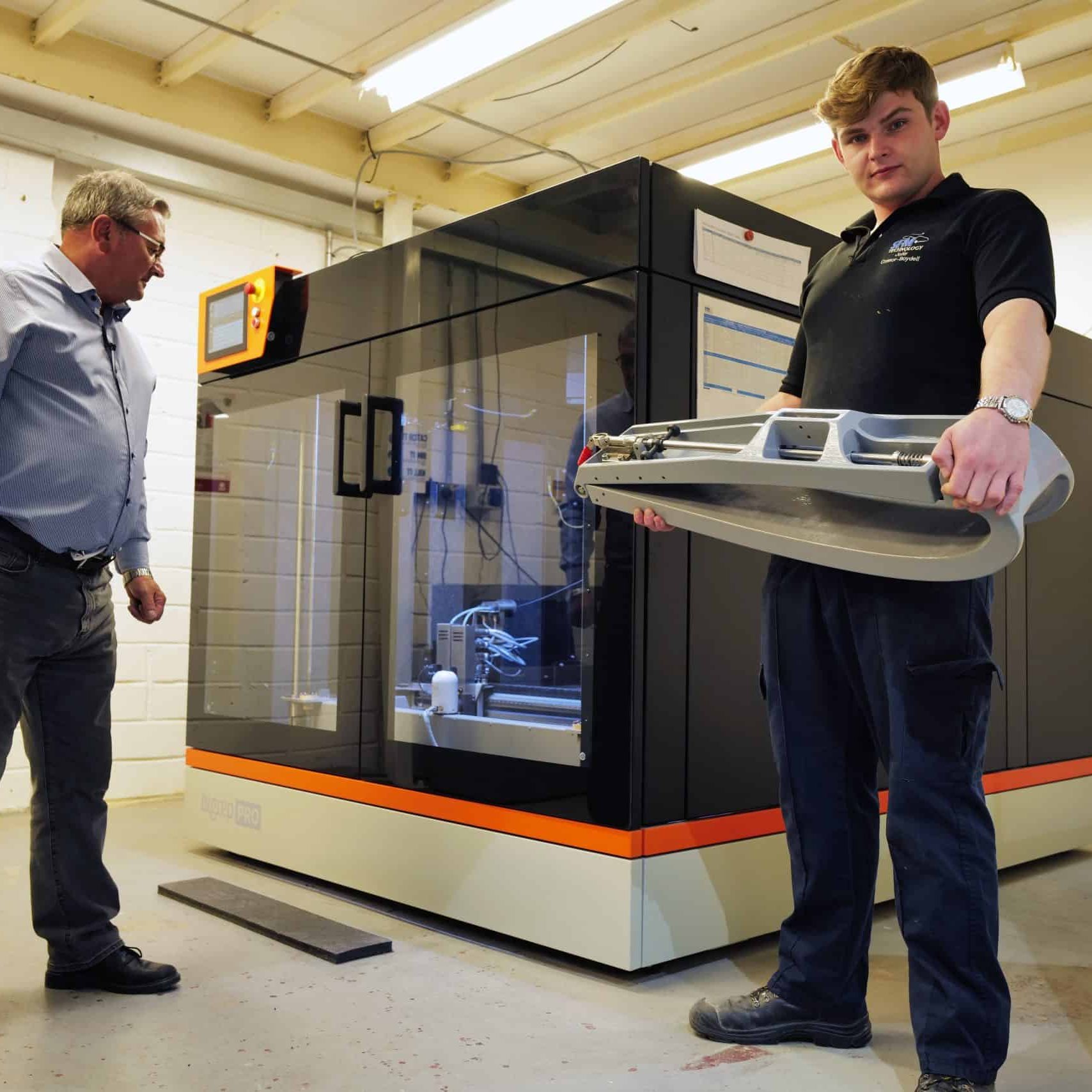

In 2020, Norwegian firm CNE Engineering worked with Scandinavian Airlines (SAS) to rapidly develop engine exhaust covers for the increased number of grounded planes during the early days of the Covid-19 pandemic. These covers were necessary to protect the unused aircraft engines from the harsh Scandinavian winter as well as other debris and moisture. However, they also had to be easy to remove, since the engines required regular operation and testing while grounded.

SAS did not have enough off-the-shelf engine covers or other required equipment on hand, so it recruited CNE Engineering to develop a solution that would both protect the engines and circumvent the supply chain issues that arose in the pandemic. The result was a large-scale urethane exhaust cover that was cast using a 3D-printed mold.

The mold itself had to withstand the urethane casting process, which led the CNE Engineering team to use a combination of BigRep PLX and HI-TEMP CF filaments. BigRep PLX was used for the top and bottom part of the tool (printed on the BigRep ONE), while the center core was made from HI-TEMP CF. PLX offered fast production speeds for the large tooling and the necessary strength and resistance. HI-TEMP CF, for its part, offered enhanced thermal resistance and durability for the casting process. In the end, the 3D printed tool enabled the rapid production of many exhaust covers, which saved SAS significant assembly and disassembly time for its aircraft engine maintenance. The use of BigRep 3D printing also allowed for a rapid turnaround: CNE Engineering delivered SAS’s first order within just two months of being approached.

Physical properties:

| Material: | Polylactic Acid Blend |

| Filament Sizes: | 2.5, 4.5 and 8.0 kg |

| Diameter: | 2.85 mm |

| Density: | 1.25 g/cm³ |

| Flexural Modulus (ISO 178): | 2800 MPa |

| Tensile Strength (ISO 527): | 48 MPa |

| Breaking Stress (ISO 527): | 3000 MPa |

| Hardness (Shore): | D 70 |

Recommended printing conditions:

| Nozzle Temperature: | 210 - 220 °C |

| Print Bed Temperature: | 60 °C |

| Printing Speed: | 40 - 120 mm/s |