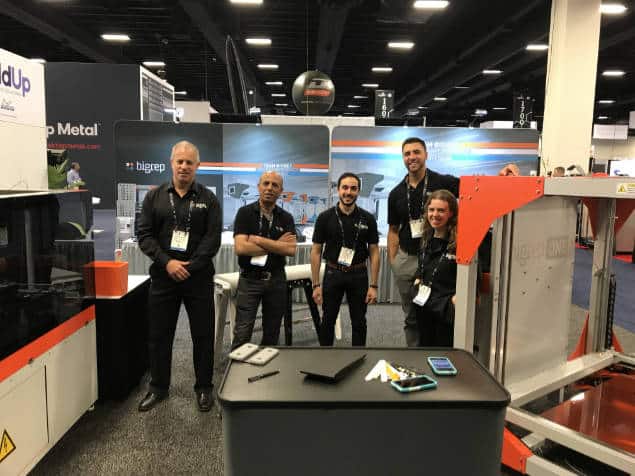

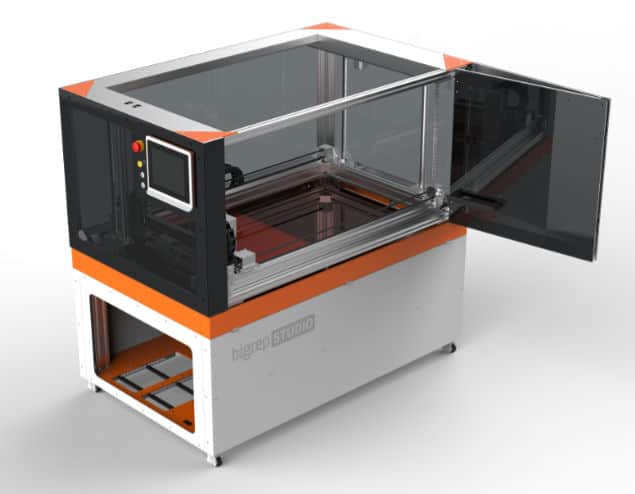

This summer heralds a big change for the rapidly expanding CAD MicroSolutions. They’re looking to move into their new, larger headquarters in Toronto, Canada, which will also serve as their demo facility. As one of the most recent partners to join the BigRep reseller community, they plan to showcase one of our machines on the demo floor – BigRep’s are the first large-scale printing machines they have added to their portfolio of 3D printers.

“BigRep was the sweet spot,” said Hargurdeep Singh, Director of Additive at CAD MicroSolutions. “We were missing the large-build envelope from our portfolio.” He zeroes in on what it was about the technology that motivated them to bring BigRep products to their customers: namely, the open source technology regarding materials and German engineering.

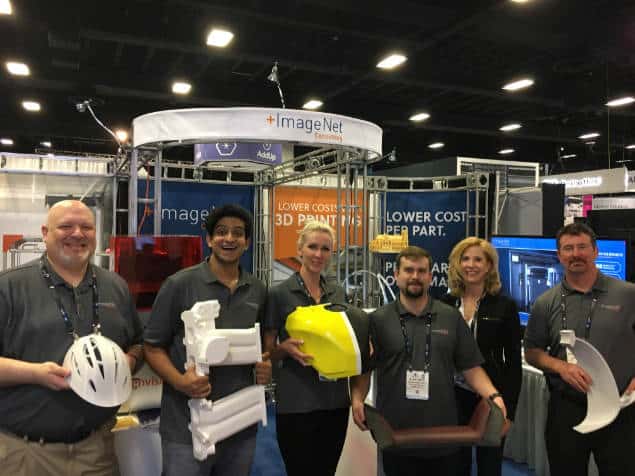

The Canadian firm has been servicing businesses across the country providing mechanical and electrical CAD solutions since 1984. They have expanded into additive manufacturing as well as VR/ AR and IoT solutions. At the helm of CAD MicroSolutions’ additive program, Singh and the team are based in Toronto, with an office in Cambridge and representatives across Canada, including in Montreal and Ottawa. They have a strong technical team, providing both remote and field support, as well as customized training.

Long-time resellers of Solidworks, CAD MicroSolutions was very selective as they expanded into additive manufacturing. They wanted to be sure their technology partners provided solutions that their clients would value. Singh says this has worked to their advantage. He explains that they are now in an advantageous position, being able to pick the solutions that best fit customer needs.

There’s a core focus on education, as training lies at the heart of what they do. Offering webinars, assisting SMEs find funding to explore additive manufacturing potential, and more, CAD MicroSolutions is intent on spreading the word about 3D printing technology. Singh said, “We don’t just want to sell a box,” – it’s ideas and potential they want to offer, as their company tagline ‘Innovation Enablers’ indicates. Students are, in his view, the ‘future force’, as they’re going to make equipment recommendations to their future employers.

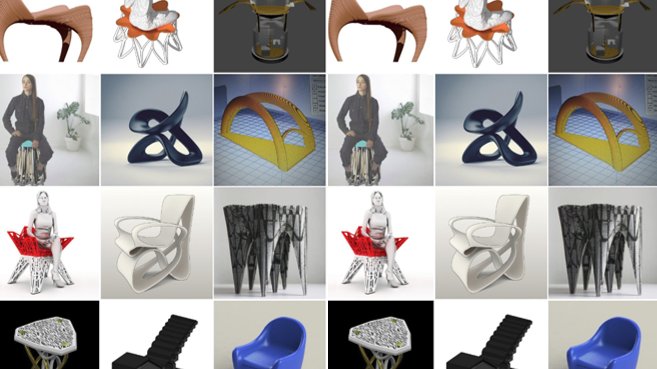

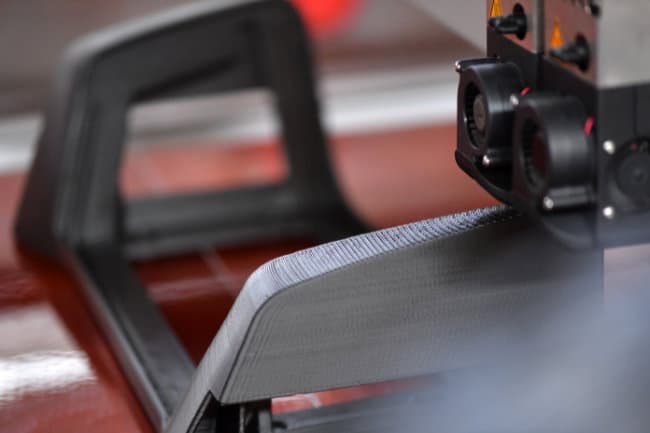

The company has also recently partnered with the Canada Makes network, which is a manufacturing industry-led initiative to boost Canadian innovation by encouraging adoption of additive manufacturing technologies. CAD MicroSolutions has seen enormous potential in Canada for shortening production cycles in the furniture industry with large-scale additive manufacturing. Singh said, “It has become very much like the fashion industry – they want to feel, touch, analyze the product. You just can’t do that digitally, so you need a physical, life-sized model in front of you.”

As well as working with the furniture, foundry, and mechatronics industries, CAD MicroSolutions sees the immense possibilities for educational institutions to further explore industrial 3D printing and specifically additive manufacturing. For Singh, it’s personal. “If I hadn’t had the chance to use, to play with them [a 3D printer] at my university, I don’t think I would have the passion and the desire I have today for additive.”

It’s a lucky thing he did come across a 3D printer in his institute, as it spurred the researcher on to win a host of accolades for the papers he has written on the subject, such OACETT’s Best Publication Award in Year 2014, for his paper titled ‘Cost Optimization of FDM Additive Manufactured Parts’. Singh has a technical research and development background, with a mechanical engineering specialty, and joined CAD MicroSolutions in May 2017 to head up their additive manufacturing division.