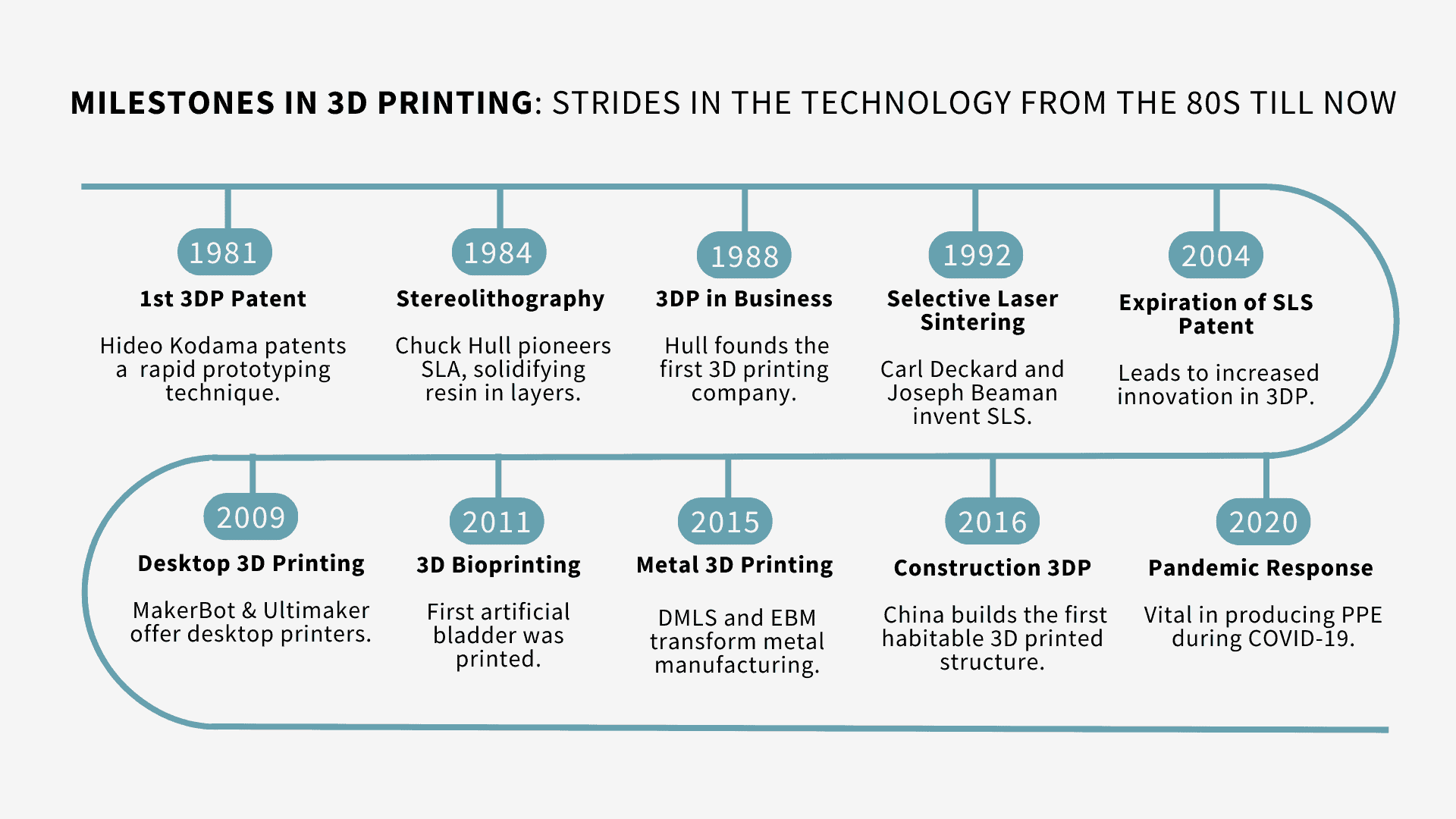

What possesses someone to reinvent a musical instrument that’s been around for thousands of years?

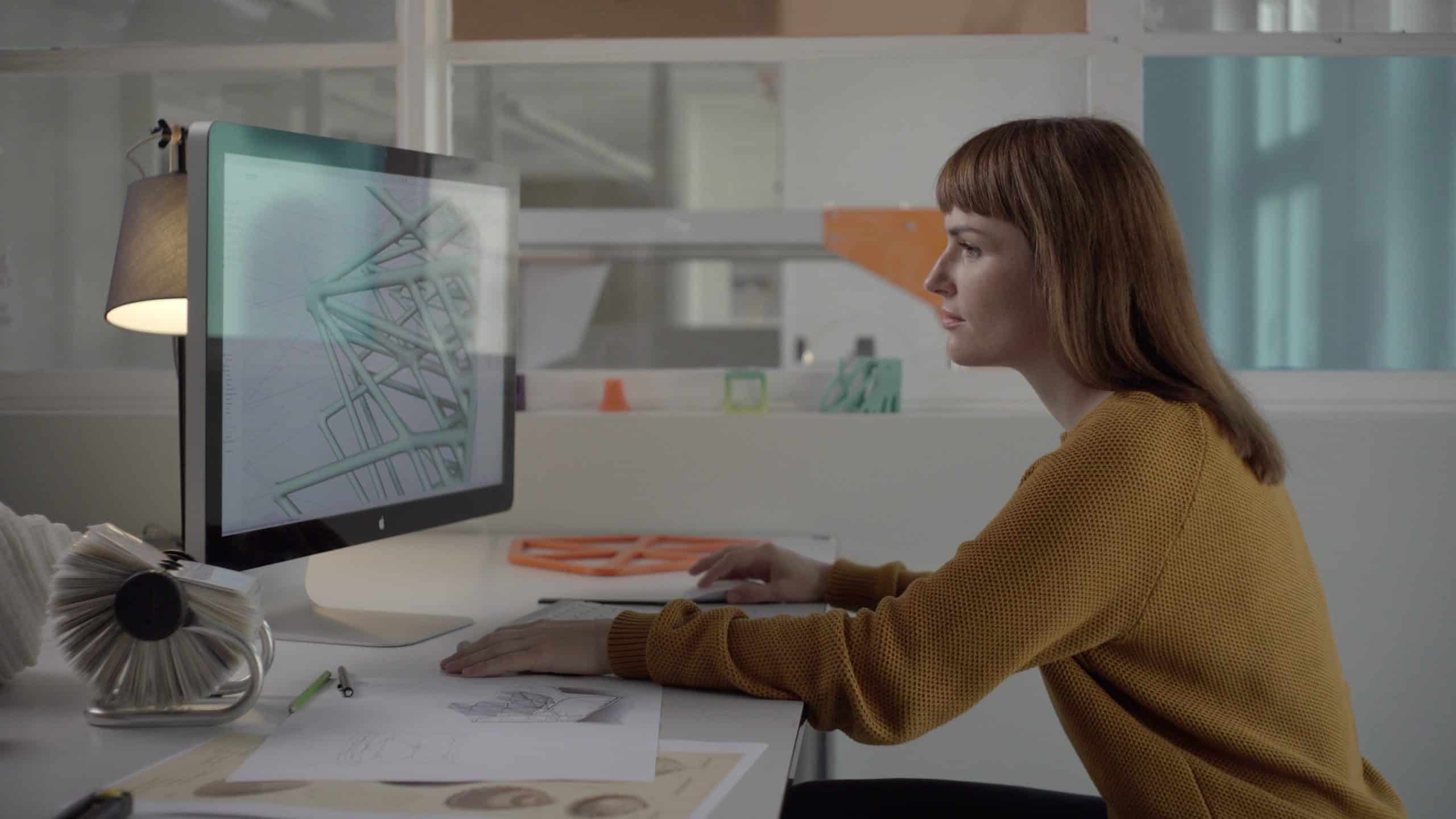

Oliver Deeg, a product engineer, and musician will tell you: boredom, curiosity, and a firmly rooted knowledge of additive technology. His dream? To create drums that aren't confined by traditional manufacturing limitations. His tool of choice? Large-format 3D printing.

Defying Conventional Constraints

Oliver Deeg is a man of talents and passions; CAD design, additive 3D printing technology, and e-commerce being the mainstays. His vision is to push the boundaries of design and music through Additive Manufacturing.

Like most drummers, customizing and building his own drum kit has always been his dream. His journey began alongside a friend crafting drum sets in wood, but the constraints of traditional methods held him back from making the design truly his own.

Meticulous woodworking is the time-tested way of crafting a bass drum. It begins with selecting quality wood like maple or birch, dried to prevent warping. Wooden staves are shaped and glued together to form a cylinder, creating the drum's shell. Precise bearing edges are then cut to optimize contact between the drumhead and shell, crucial for tone. The holes are then drilled for hardware, and the shell undergoes thorough sanding and finishing. Drumheads, made of synthetic or animal skin, are attached using tension rods. Finally, the hardware is assembled, and fine-tuning adjusts the drum's tension rods for the desired pitch and resonance. This intricate process demands skilled craftsmanship and attention to detail to create a bass drum.

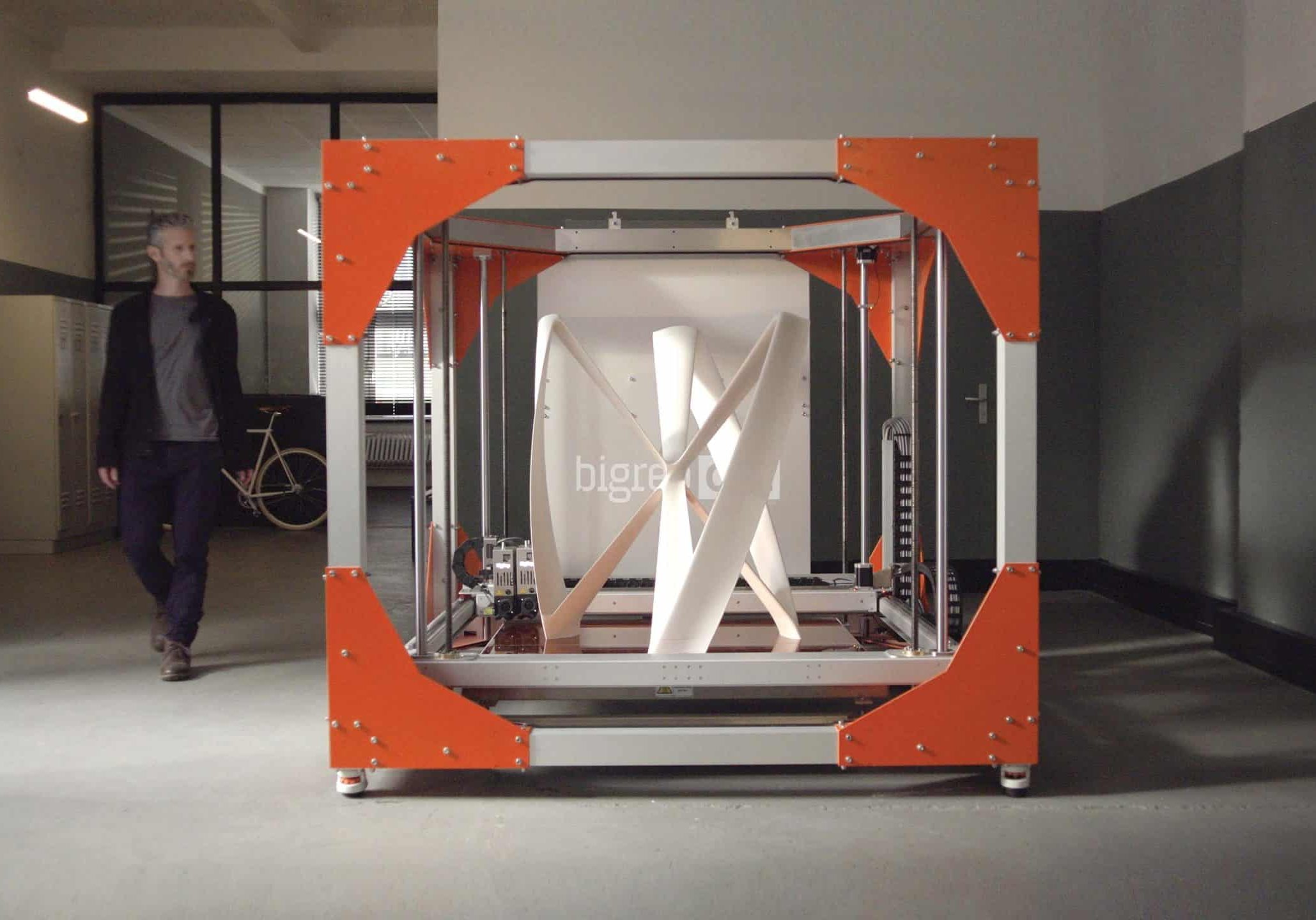

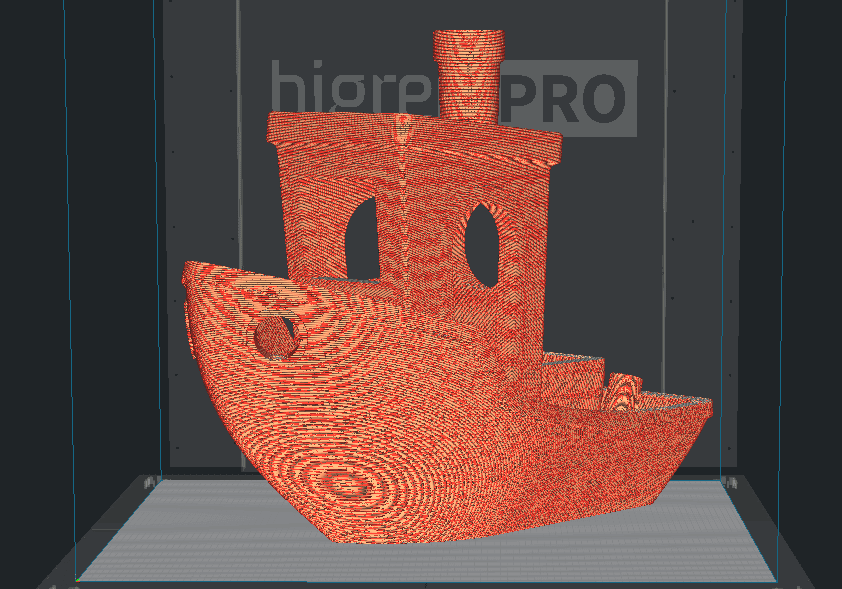

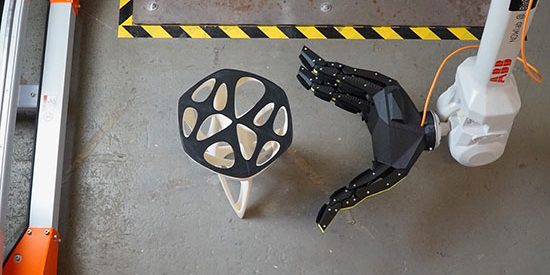

This process has been stagnant and leaves little room for experimenting with sound and design. Oliver saw the potential to produce drums that would be free of these limitations. He turned to 3D printing and his expertise in Additive Manufacturing proved advantageous, with which he began producing small drums. From small prototypes, his ideas snowballed into more ambitious projects. True to the heart of a musician and the mind of an engineer, he couldn’t help thinking BIGger.

"With 3D printing, it was the first time that I felt there are no real borders. You conceptualize an idea, and within hours, you hold a tangible prototype. It's such a dream come true”

Dreaming BIG

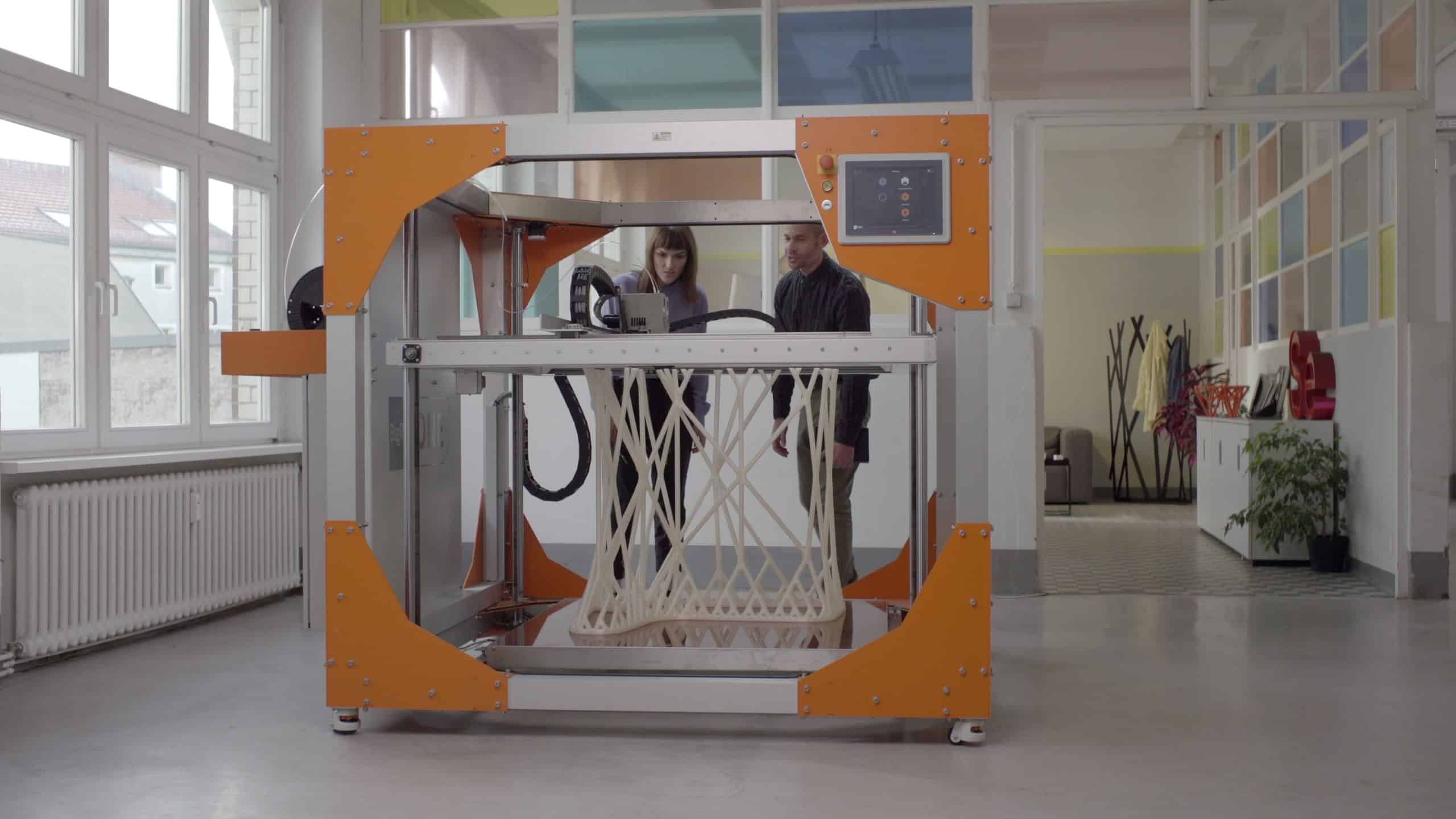

The turning point came when Oliver crossed paths with BigRep at Formnext 2022 which led to a collaboration that propelled his vision forward. BigRep's range of materials and large-format 3D printers were instrumental in materializing his vision - A 24 Inch Base Drum with 6 USPs:

- Cone-shaped inner shell to explore new unique sounds.

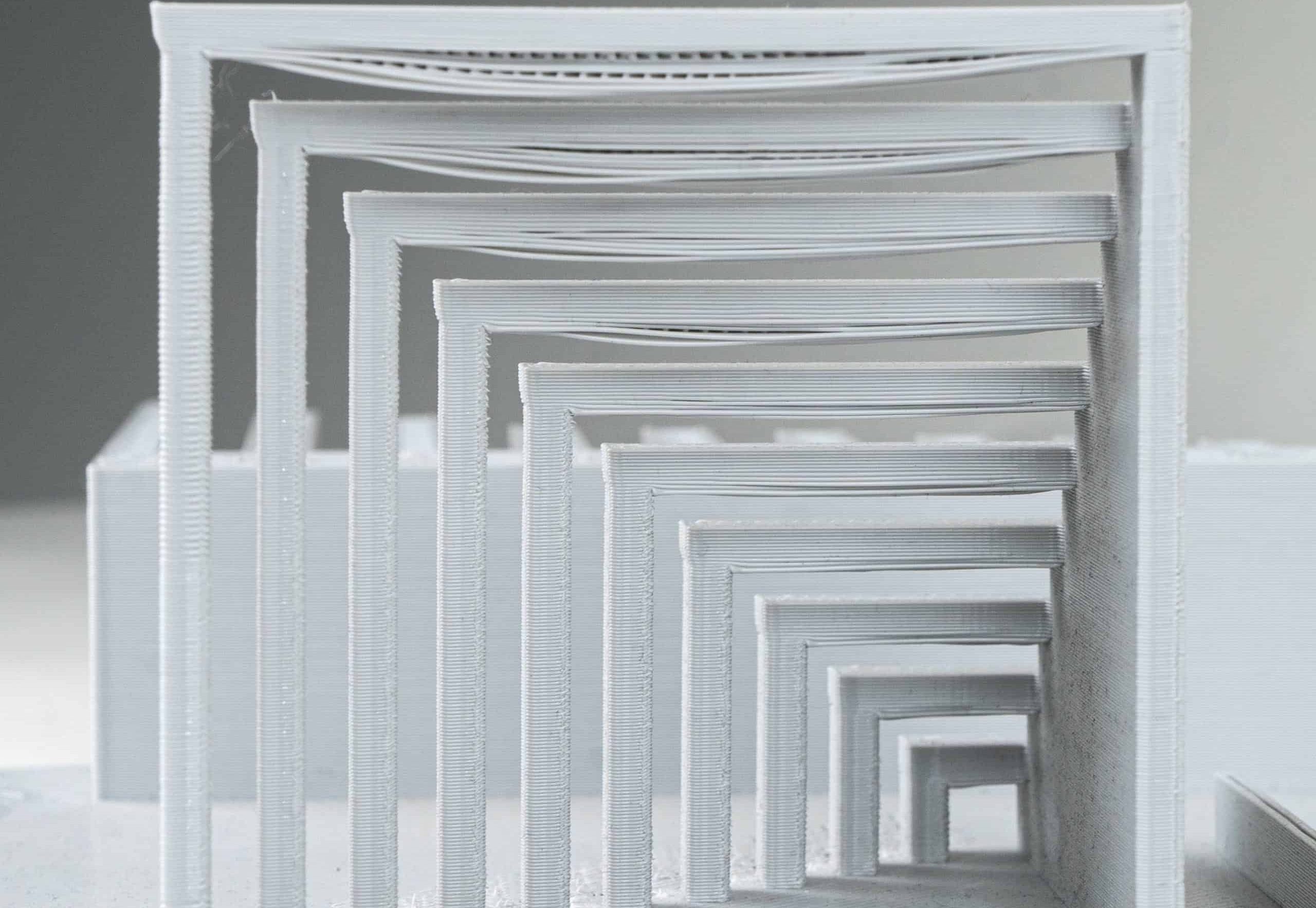

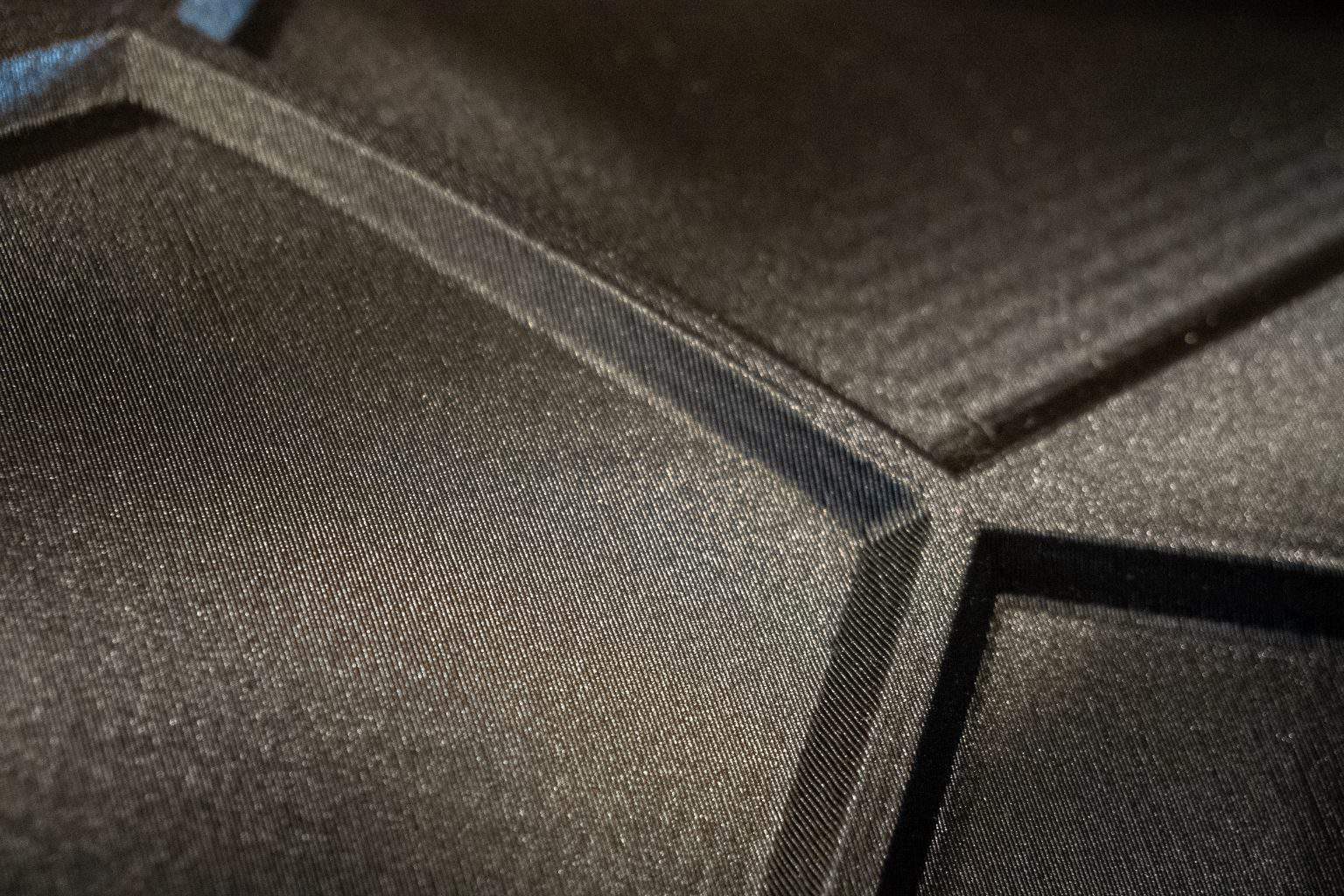

- Relief shell design for stability and an aesthetic finish.

- Sound + cable hole to release air pressure and also double up as a means to insert microphones into the drum.

- Hollow-shaped fill hole to hold granulates such as sand or can also contain water. When empty, it produces more of a violin-like sound, and when filled, results in lower frequencies.

- Customized hoops to hold the drumhead.

- Experimentation with a range of materials to find the best sound, fit, and finish.

He adds,

"The collaboration with BigRep was a game-changer. Their advanced printing capabilities enabled the creation of drums with exceptional quality."

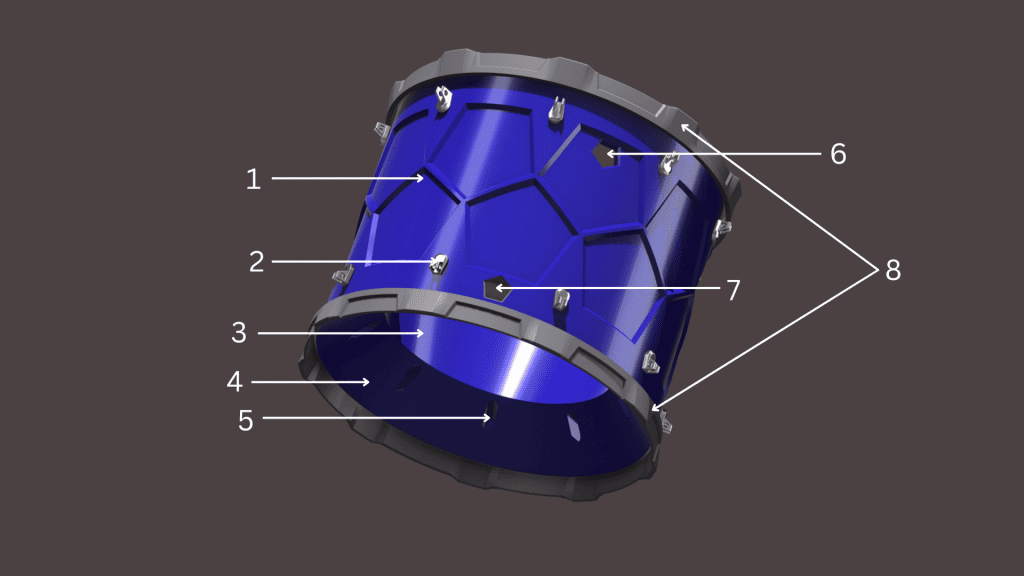

Anatomy of the 3D Printed 24-inch Bass Drum

- Relief Shell Design For stability and an aesthetic finish.

- Holes for lugs Space for metal lugs to hold the tuning screws.

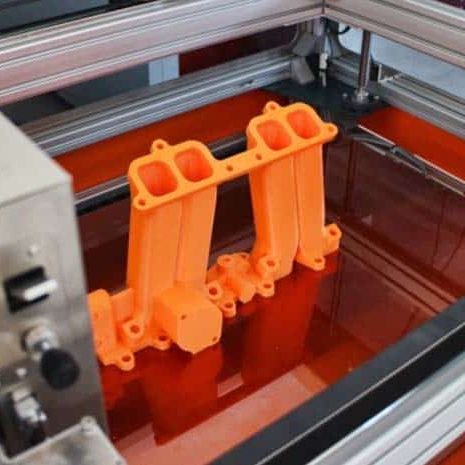

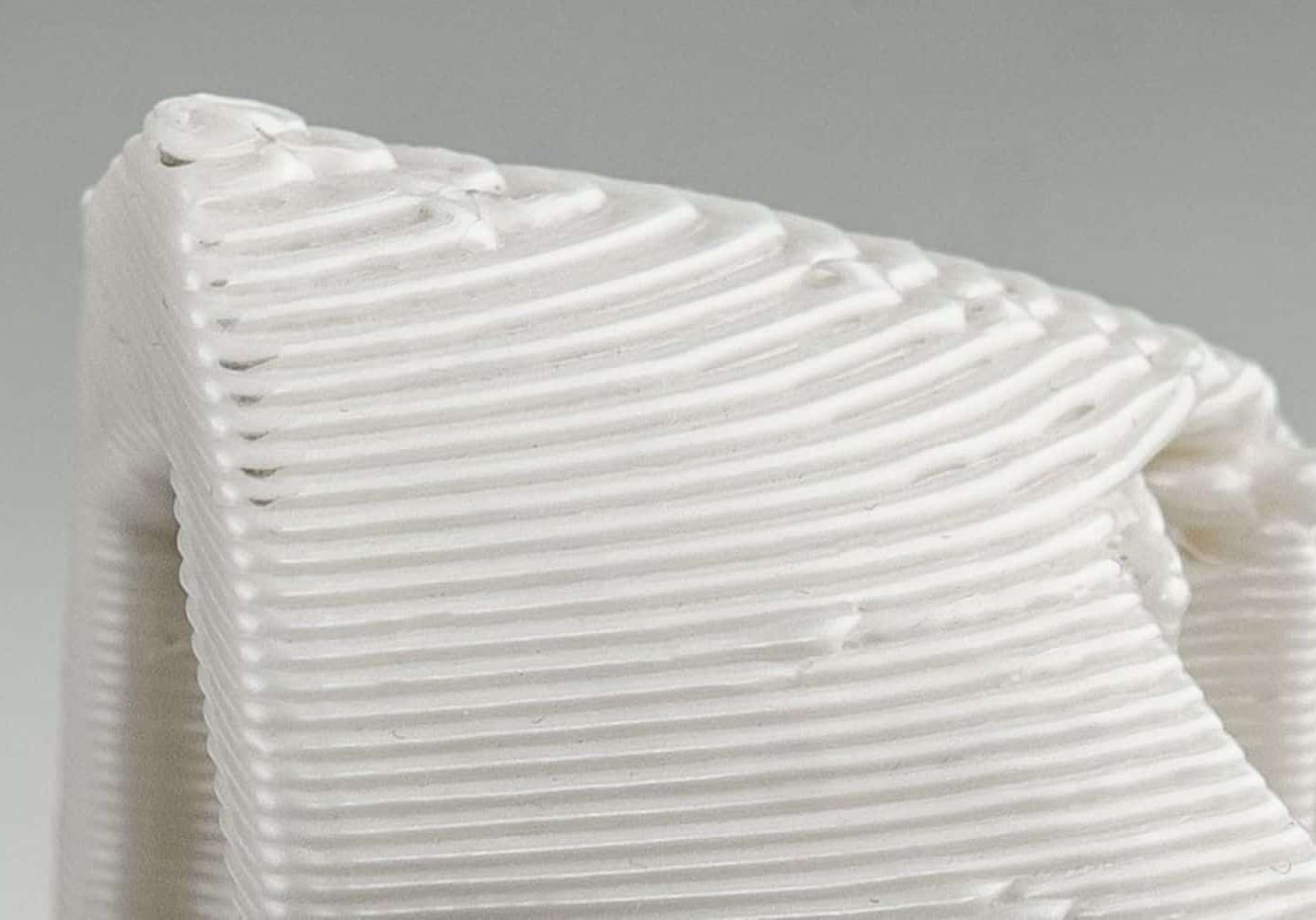

- Cone Shaped Inner Shell Crafted like a megaphone, it is instrumental in creating new sounds.

- The Drum Shell Main body of the drum.

- Screw Holes To secure lugs from the inside.

- Sound and Cable Hole Releases air pressure and doubles as a space to insert microphones inside the drum.

- Hollow Shell with Fill-Hole for granulates such as sand or can also hold water.

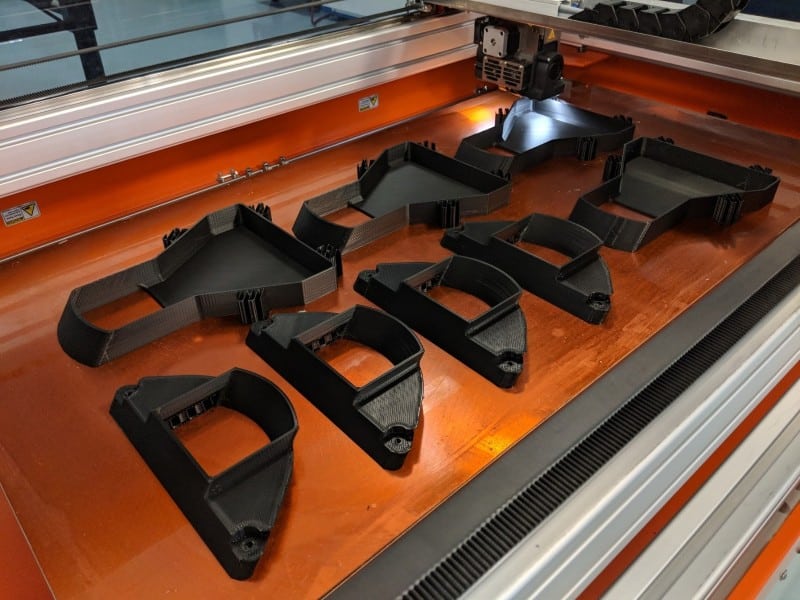

- Hoops to hold the drumhead crafted for the 3D-printed shell. Produced twice.

Oliver's drum set is an embodiment of unconventional acoustic principles. Inspired by how sound amplifies in conical shapes, his design incorporates two shells with an acoustic space between them—a feat unattainable through conventional methods.

He elaborates,

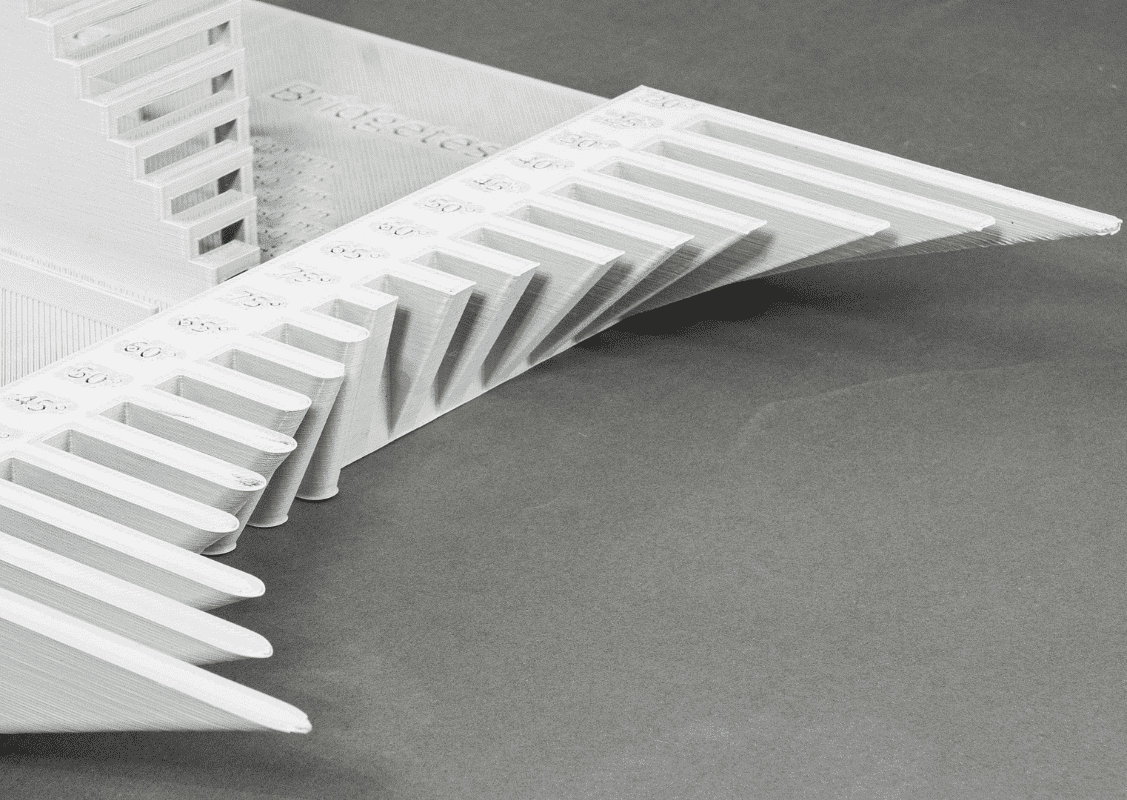

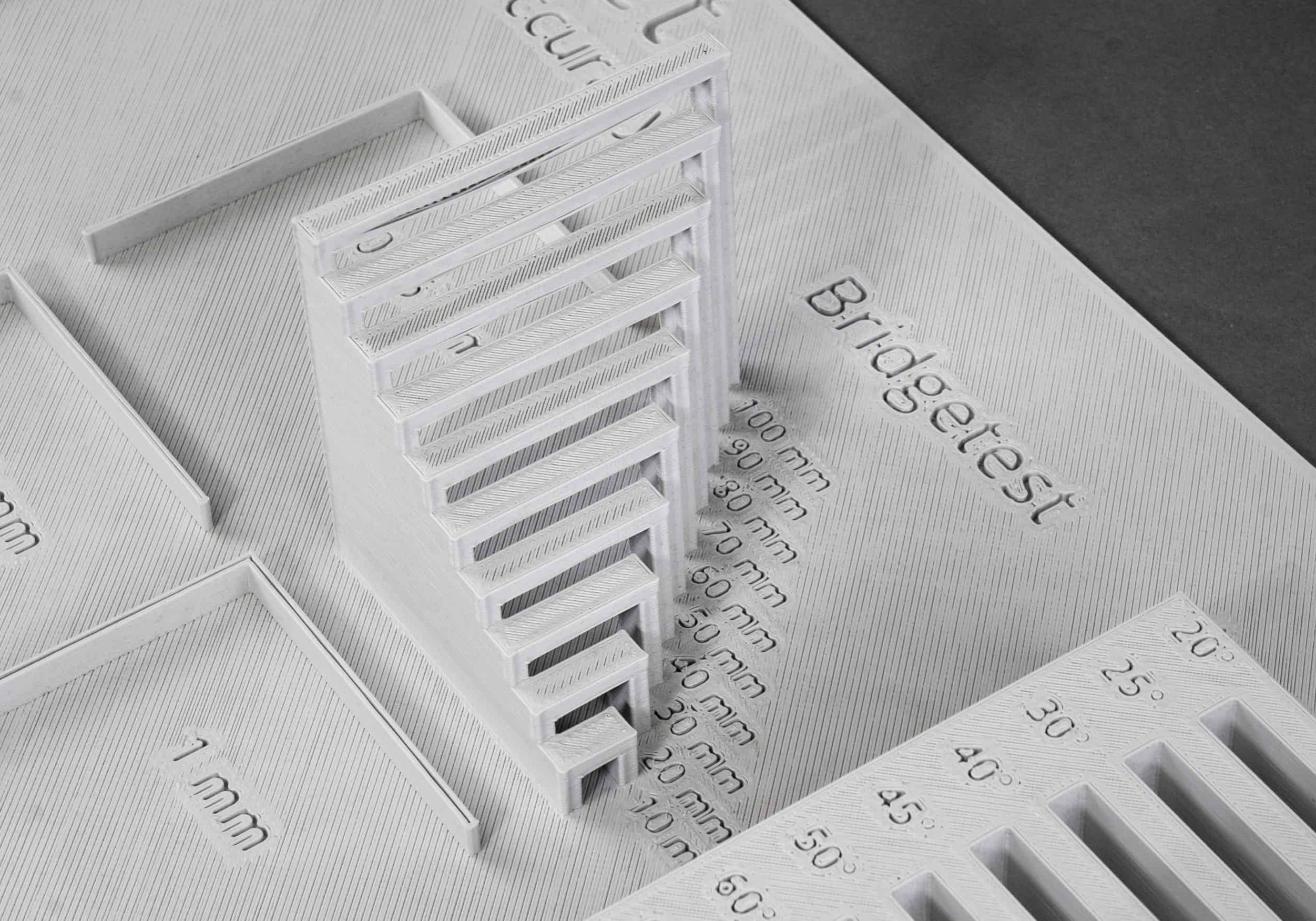

"Finding the right material and producing a large-scale print of this size was the biggest challenge. The drum took a few days to print. The surface, straight from the printer, was immaculate, there was no need for post-processing."

3D Printing Hits the Right Note

Plastic drums are nothing new, they’ve been around for a while. But they all have a distinct sound and feel that doesn’t stand out the way that the 3D-printed bass drum does. The very first impression of the drum for Oliver was that it sounded incredible. Not only did the sound and design deliver, but also the material and construction of the drum held its ground. When he put it under the microphone in the studio, the real difference showed up. It did not just compete with a regular drum but also sounded distinct because of its USP – The Conical Inner Shell.

Starting out, Oliver knew designing the 3D file, pushing print, and producing the drum parts wasn’t going to be a simple ride. What is usually perceived as easy geometry is not, and the drum required expertise and accuracy that, along with BigRep, he was able to achieve making him a firm believer that the next wave of drum customization belongs to Additive Manufacturing.

Given his fascination with 3D printing technology, it’s no surprise that he sees it as not just being a catalyst for a new era in creating musical instruments but also integrating into our everyday lives. For him, the future holds a fascinating prospect—a world where every household could house a 3D printer, becoming an answer for personalized on-demand production.

“I envision a day when a 3D printer sits in every home, where ordering something means it materializes straight out of your own printer,"

Oliver concludes.

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

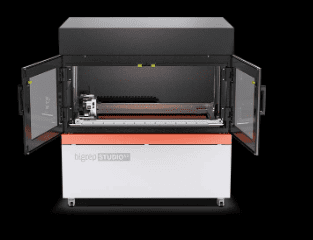

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.

LARGE-SCALE INNOVATION. LIMITLESS CREATIVITY.

The BigRep ONE is an award-winning, large-format 3D printer at an accessible price point. With over 500 systems installed worldwide, it's a trusted tool of designers, innovators, and manufacturers alike. With a massive one-cubic-meter build volume, the fast and reliable ONE brings your designs to life in full scale.